About Seamark

Founded in Shenzhen, the heart of global manufacturing, Seamark has grown from a specialized parts maker to a comprehensive solutions provider. Our journey is marked by continuous innovation, expanding capabilities, and an unwavering commitment to quality.

Our team of skilled engineers and technicians combines years of experience with state-of-the-art technology to deliver exceptional results. We pride ourselves on our ability to tackle complex projects, our attention to detail, and our dedication to customer satisfaction.

Our Expertise

DFMA Feedback

We continuously provide free DFMA feedback so that your design is the best feasible design, and your project runs well.

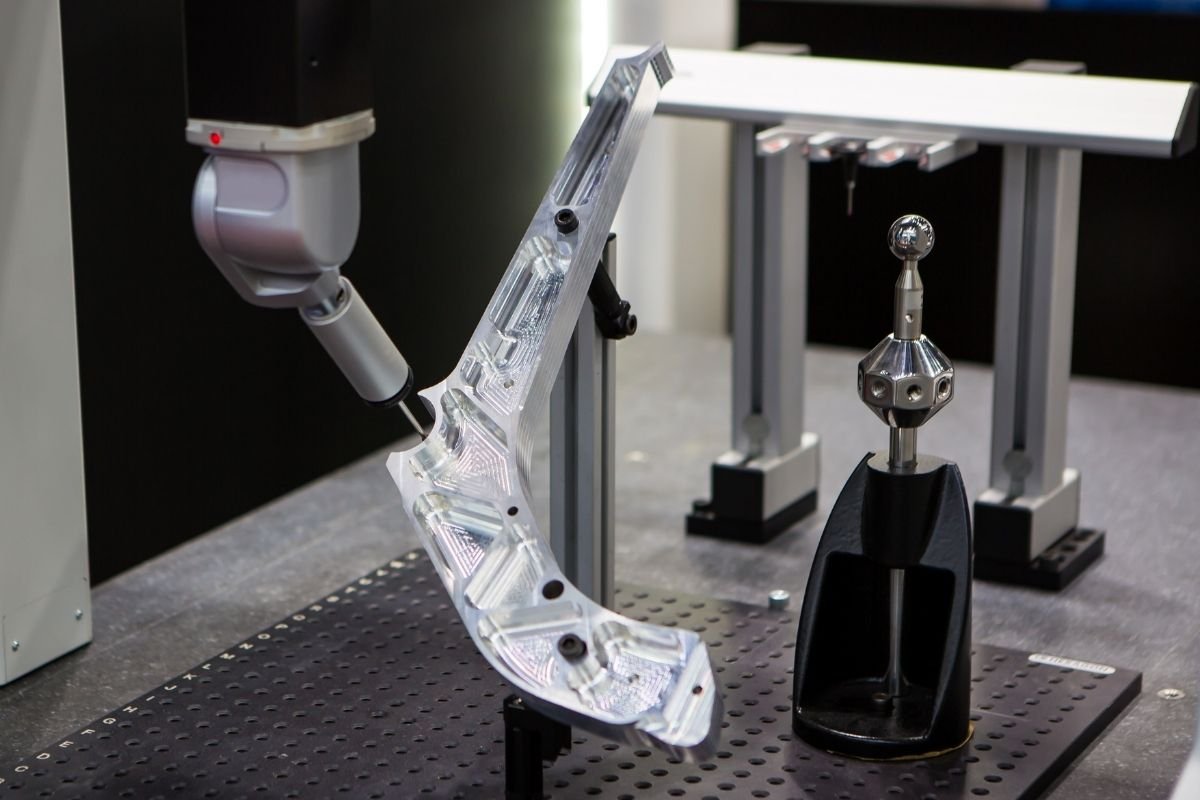

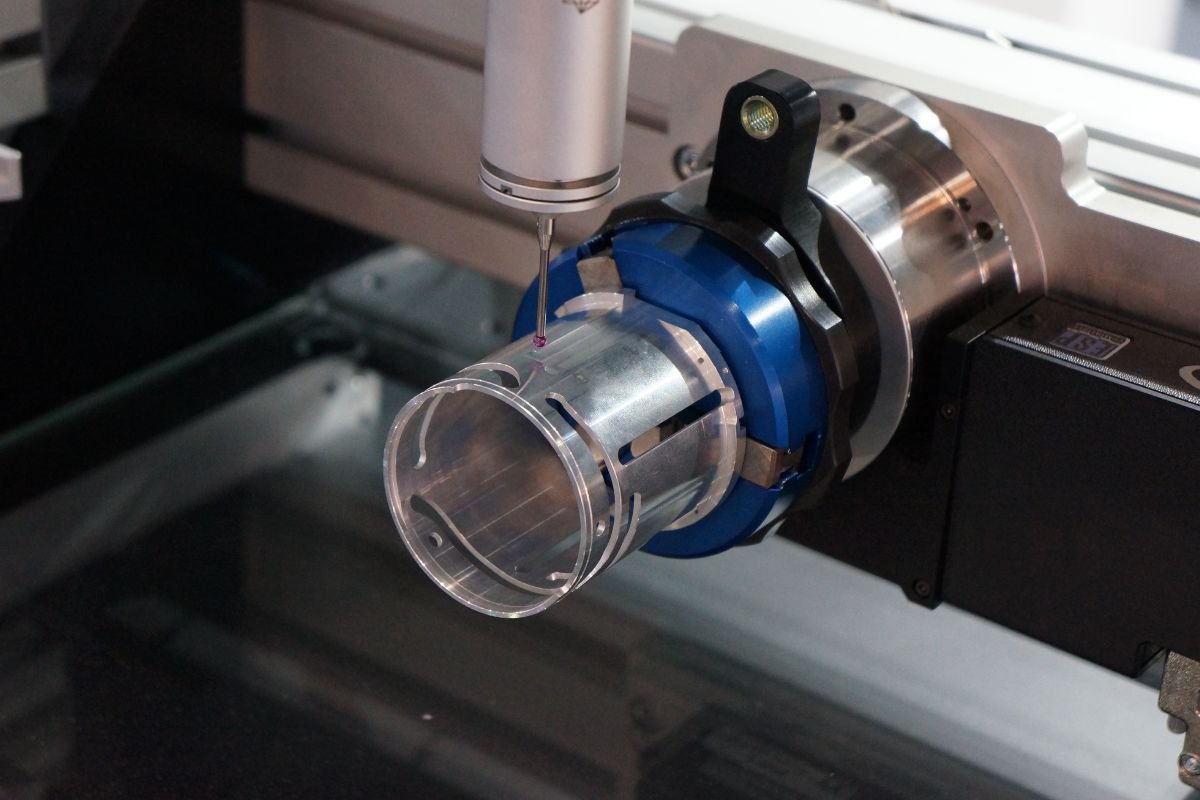

Quality Assurance

We rigorously test our products to ensure that they meet or exceed industry standards and customer expectations.

Customer Service

We understand the importance of clear communication and prompt response times, and we strive to exceed customer expectations in every interaction.

Why Trust Us

Seamark’s expertise in engineering and machining allows us to work with a diverse range of materials and projects, ensuring that we can meet the specific requirements of your project, regardless of the material type.

Experience

15 Years of industry experience delivering high-quality CNC machining solutions.

Expertise

Skilled professionals and advanced technology ensure precision and excellence.

Quality

ISO 9001 certification guarantees top-notch quality control and consistent results.

Customer Satisfaction

Our focus on customer needs ensures a positive experience and successful outcomes.

Happy Stories

We aim to be a trusted partner and a driving force in the machining industry, contributing to the success and growth of our customers.

Frequently Asked Questions

We support all major CAD file types including STEP, IGES, STL, OBJ etc. Designs should be in solid model format for best results.

For standard plastics like ABS and PLA, we can deliver prototypes within 5-7 business days after receiving your design files. More complex projects may take up to 2 weeks.

Yes, we can add moving parts, electronics integration and finishing touches to make prototypes as functional as possible for testing.

We offer surface finishing, assembly, hardware integration and other treatments to make prototypes look and function like finished products.

We respect your intellectual property. None of your information, images, files or likenesses will be shared with any third party, and it will not be used for any advertising, marketing, or promotional use without your explicit written authorization. If you would like to sign NDA agreement, please contact our team for support.

We follow the ISO/IATF standard and guarantee that we will rework the products or refund them if there are any quality problems. The full-dimensional report, material certification, or first article inspection are provided on request before order placement.