Our Service

From initial concept to final delivery, our comprehensive services cover every step of the product development process.

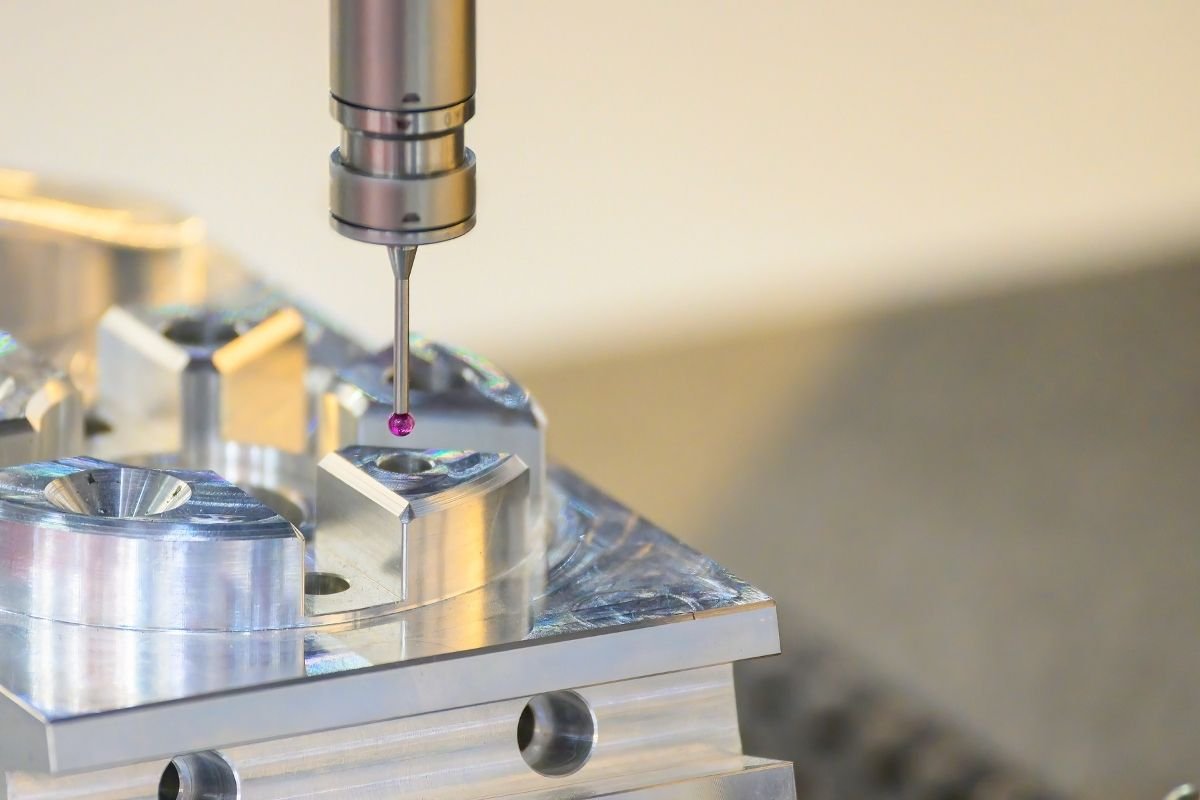

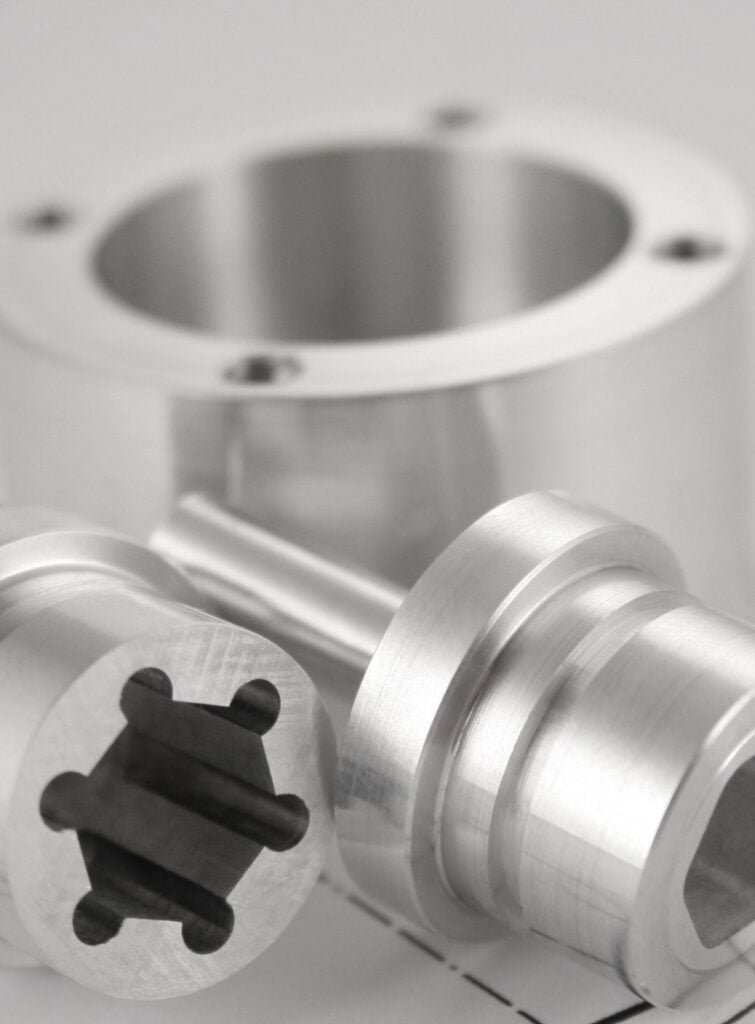

Usinage CNC

Précis et polyvalent, l'usinage CNC offre des pièces personnalisées de haute qualité avec des tolérances serrées, adaptées à divers matériaux

Fabrication de tôles

Idéale pour les conceptions complexes, la fabrication en tôle offre des solutions durables et économiques pour les boîtiers, les supports et autres composants métalliques.

Moulage par injection

Efficace et évolutif, le moulage par injection permet une production en grand volume de pièces en plastique avec une excellente répétabilité et des détails complexes

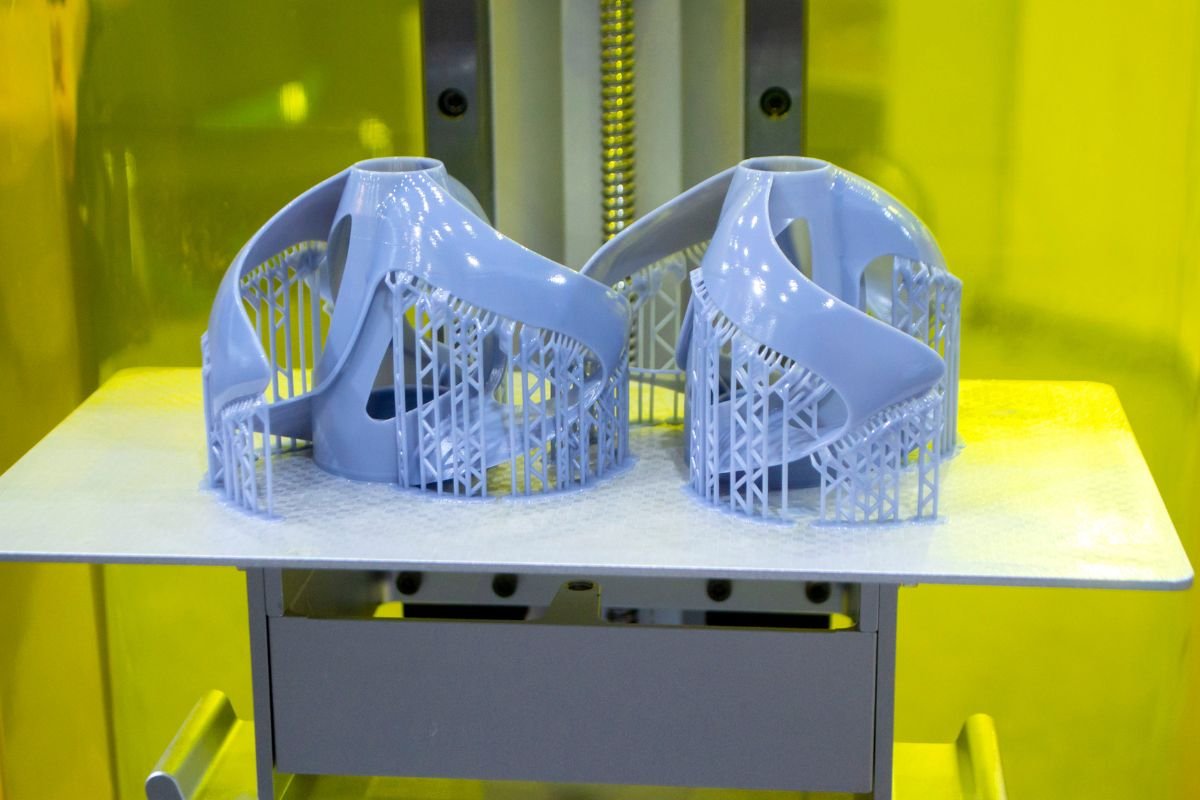

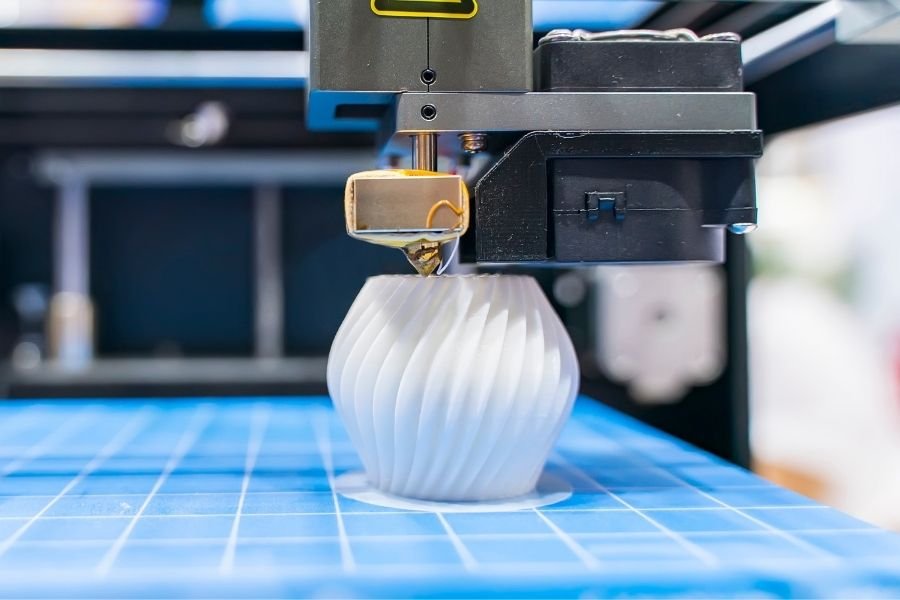

impression en 3D

Prototypage rapide et production à faible volume facilités grâce à l'impression 3D, permettant des itérations rapides, des géométries complexes et une large gamme de matériaux

Coulée sous vide

Offrant une production en faible volume avec des répliques de haute qualité, la coulée sous vide permet la production de prototypes fonctionnels et de pièces finales dans divers matériaux

Production à faible volume

Low-volume Production allows for cost-effective production without the high tooling investments of mass manufacturing, enabling you to scale gradually and make design tweaks as needed.

One-stop Manufacturing Solutions

Que vous ayez besoin d'un prototype unique pour la vérification de la conception ou la fabrication en série de produits finaux, nous sommes là pour vous aider.

Prototypage rapide

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

Production à faible volume

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

Production de masse

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Galerie de notre travail

Nous fabriquons une large gamme de pièces en métal, en plastique et de prototypes de haute qualité pour des clients du monde entier.

Pourquoi nous

Chez HeyguMake, nous sommes fiers de notre vaste expertise en génie mécanique. Notre équipe de professionnels se consacre à fournir des produits et services de la plus haute qualité à nos clients.

Compétence

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

Assurance qualité

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Happy Clients

Questions fréquemment posées

Absolutely. We provide a range of post-processing services includiWe accept most common 3D CAD file formats, including:

- STL (preferred)

- OBJ

- STEP

- IGES

- Solidworks files (.sldprt, .sldasm) If you have a different file format, please contact us, and we’ll do our best to accommodate your needs.

ng surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.

Turnaround times vary depending on the complexity of the project and the manufacturing method used. For simple projects, we can often deliver within 3-5 business days. More complex projects may take 1-2 weeks. We recommend contacting us directly for a more accurate estimate based on your specific requirements.

While we primarily work with customer-provided 3D models, we do offer basic design assistance and can help refine your existing designs for manufacturability. For more extensive design work, we can recommend trusted partners or discuss your needs on a case-by-case basis.

We work with a wide range of materials including various plastics, metals, and composites. Our capabilities include ABS, PLA, and resin for 3D printing; aluminum, steel, and other metals for CNC milling and sheet metal work; and a variety of resins for vacuum casting. We can discuss specific material requirements for your project.

Yes, we specialize in both rapid prototyping and low-volume manufacturing. Our services are scalable, allowing us to produce anywhere from a single prototype to several hundred units, depending on your needs and the manufacturing method used.

Absolutely. We provide a range of post-processing services including surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.