Rapid prototyping refers to technologies that allow for quicker creation of engineering prototypes and products compared to conventional methods like CNC machining. With rapid prototypes, design iterations and testing can be done rapidly. This speeds up product development cycles significantly. Let’s explore more about rapid prototyping and its applications in engineering.

What is Rapid Prototyping?

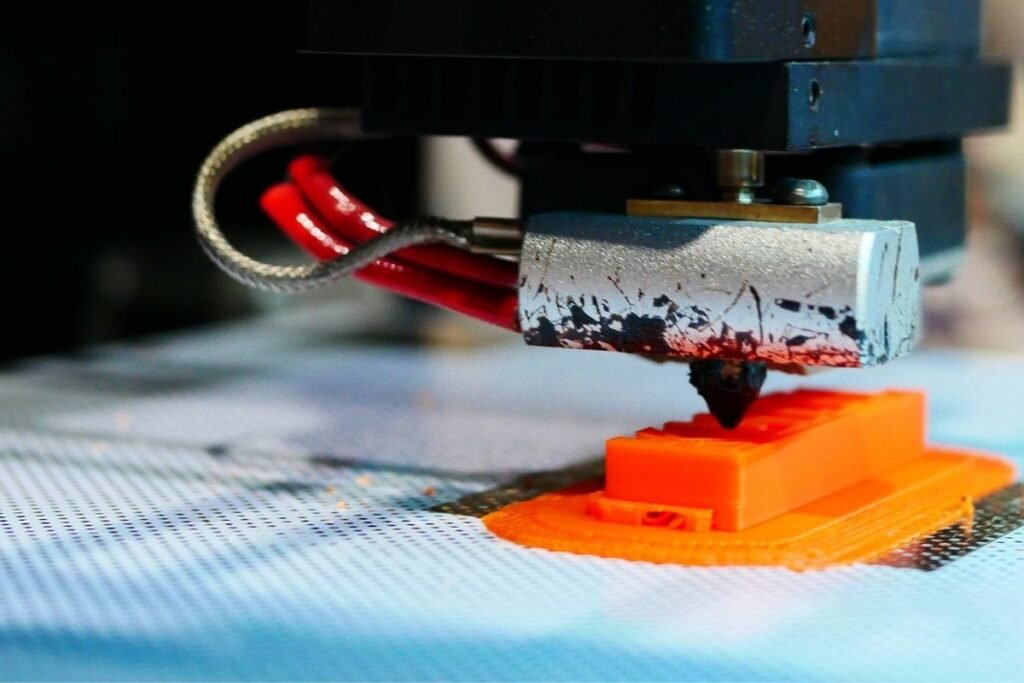

Rapid prototyping is a group of techniques used to quickly create a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. In rapid prototyping, the model is built by additive manufacturing methods where layers of material are laid down in succession until the model is complete. This is an automated fabrication process unlike manual prototyping techniques.

The data input for rapid prototyping is a CAD model created in software like AutoCAD, SolidWorks, CATIA, etc. The CAD model is converted into thin horizontal cross-sections by the rapid prototyping machine. The layers are then built up one by one to create the final prototype. 3D printing is one of the most widely used rapid prototyping technologies.

Benefits of Rapid Prototyping

Here are some of the main advantages of using rapid prototyping:

- Quick turnaround: Prototypes can be built in hours or days rather than weeks. This accelerates the product design process.

- Improved designs: Multiple iterations of a design can be tested rapidly. This leads to improved product quality.

- Lower costs: No need for expensive tooling like molds or dies. Cost per part is lower.

- Customizability: Complex shapes and features can be built easily. Fully customized products can be created.

- Reduced waste: Only the required amount of material is used to build the prototype. No milling or cutting of raw material blocks.

Types of Rapid Prototyping

There are two main types of rapid prototyping:

Additive Manufacturing

This involves creating the prototype by adding material layer upon layer. 3D printing, fused deposition modeling (FDM), stereo lithography (SLA), selective laser sintering (SLS), laminated object manufacturing (LOM) and electron beam melting (EBM) are some examples of additive manufacturing based rapid prototyping.

Subtractive Manufacturing

Here the prototype is made by cutting away material from a solid block. CNC machining is the most common form of subtractive rapid prototyping. The material block is milled using a computer controlled cutter to get the desired shape.

Applications of Rapid Prototyping

Rapid prototyping provides significant benefits in several industries, especially:

Automotive Industry

Rapid prototypes allow car manufacturers to quickly test styling concepts and new designs to evaluate aesthetics, ergonomics and manufacturability before full production. Wind tunnel testing of aerodynamic shapes can also be performed earlier.

Aerospace Industry

Aerospace companies use rapid prototyping to test design ideas for aircraft and spacecraft parts under simulated operating conditions. This helps find flaws and refine designs faster.

Medical Industry

Customized prosthetics, implants and models of human anatomy can be rapidly manufactured using patient scan data. This supports better diagnosis, pre-surgical planning and medical device testing.

Future of Rapid Prototyping

Advancements in additive manufacturing are enabling rapid prototyping with more materials like advanced alloys, ceramics and composites. Hybrid manufacturing which combines additive and subtractive methods will also grow. Another trend is using rapid prototypes directly as finished products rather than just as design models. With technologies improving continuously, rapid prototyping will become even more beneficial and widely adopted across engineering disciplines.

In summary, rapid prototyping leverages CAD and additive manufacturing to facilitate faster product development compared to traditional prototyping techniques. The ability to quickly create and test design iterations results in improved products in shorter timeframes. Rapid prototyping will continue transforming engineering design and production across many industries.