Case Study

One-stop machining service and low-volume production

Case Studies from Different Industry

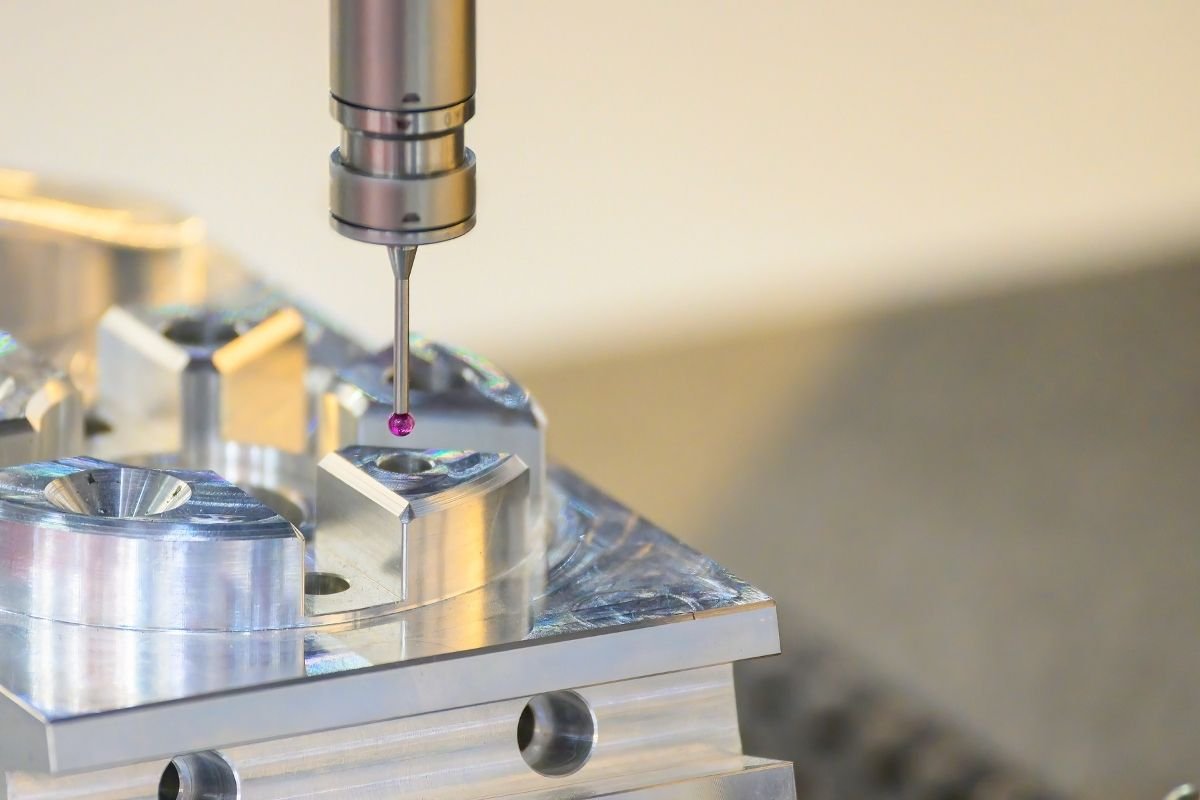

Challenge: Develop a complex, miniature component for a new minimally invasive surgical tool. Solution: Utilized advanced 5-axis CNC milling to create high-precision parts from medical-grade titanium.

Process:

- Collaborated with the client to optimize the design for manufacturability

- Developed a custom fixturing solution for the intricate part

- Implemented rigorous quality control measures to meet FDA standards Results:

- Achieved tolerances of ±0.005mm, exceeding client expectations

- Reduced production time by 30% compared to traditional methods

- Enabled the client to secure a patent and fast-track FDA approval

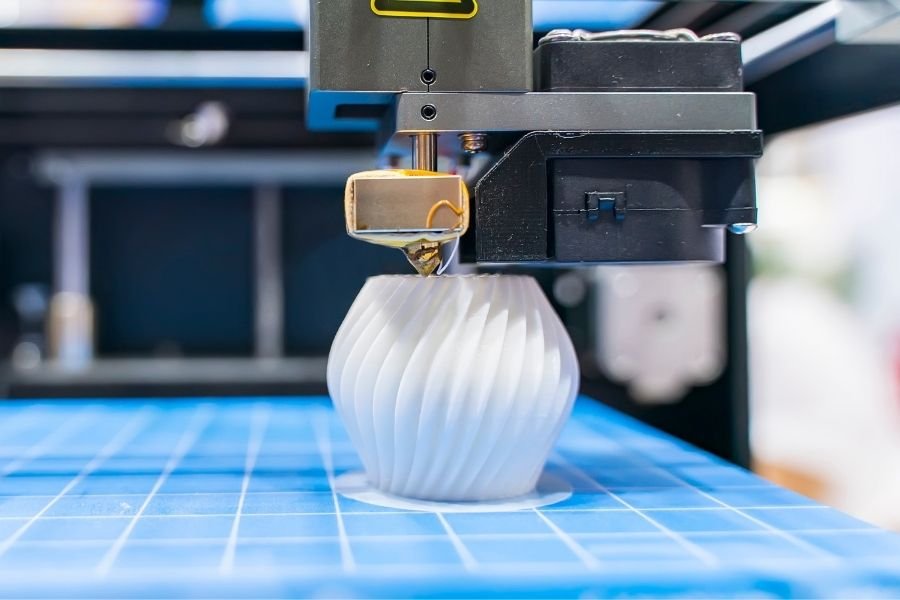

Challenge: Rapidly iterate on a smart sports watch design before finalizing for mass production. Solution: Employed a combination of SLA 3D printing and vacuum casting for prototyping.

Process:

- Used SLA for initial concept models and fit tests

- Created silicone molds for vacuum casting functional prototypes

- Provided surface finishing to achieve production-quality aesthetics Results:

- Produced 20 iterations in just 6 weeks

- Saved the client an estimated $100,000 in tooling costs for design changes

- Helped the client launch 3 months ahead of schedule

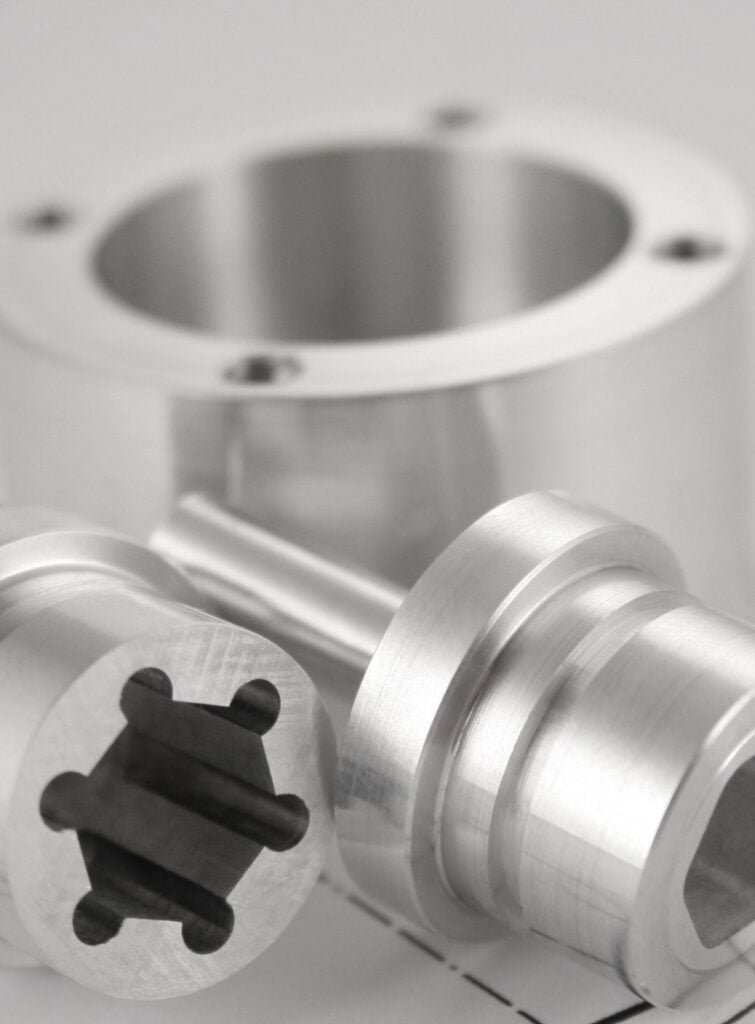

Challenge: Transition from low-volume production to meeting growing market demand for a smart thermostat. Solution: Implemented a hybrid approach using CNC machining and injection molding.

Process:

- CNC machined critical components requiring high precision

- Developed rapid tooling for injection molding of housing parts

- Established an assembly line for final product integration Results:

- Scaled production from 500 to 10,000 units per month

- Reduced per-unit cost by 40% through optimized manufacturing

- Maintained consistent quality across increased production volume

Challenge: Create lightweight yet durable control panel housings for a new aircraft model. Solution: Utilized advanced sheet metal fabrication techniques with aerospace-grade aluminum.

Process:

- Collaborated on design to optimize for weight reduction

- Implemented precision laser cutting and CNC bending

- Developed a custom anodizing process for corrosion resistance Results:

- Achieved a 25% weight reduction compared to previous models

- Met stringent aerospace quality standards with zero defects

- Helped the client secure a major contract with a leading airline

Challenge: Produce a market-test run of 5,000 units for a new educational toy before committing to full production tooling. Solution: Developed rapid tooling for injection molding, combined with 3D printed inserts for changeable features.

Process:

- Created aluminum tooling for the main body parts

- 3D printed interchangeable inserts for different product variations

- Established a flexible assembly process for various product configurations Results:

- Delivered 5,000 units in 4 weeks, meeting the client’s launch deadline

- Allowed for mid-run design tweaks based on initial market feedback

- Provided a smooth transition to full production, saving 6 weeks in time-to-market

One-stop Manufacturing Solutions

Se hai bisogno di un singolo prototipo per la verifica del progetto o la produzione in serie di prodotti finali, siamo qui per aiutarti

Prototipazione rapida

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

Produzione a basso volume

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

Produzione di massa

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Perché noi

Noi di HeyguMake siamo orgogliosi della nostra vasta esperienza nel campo dell'ingegneria meccanica. Il nostro team di professionisti è dedicato a fornire prodotti e servizi della massima qualità ai nostri clienti.

Competenza

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

Garanzia di qualità

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Domande frequenti

Supportiamo tutti i principali tipi di file CAD, inclusi STEP, IGES, STL, OBJ ecc. I progetti devono essere in formato modello solido per ottenere i migliori risultati.

Per le plastiche standard come ABS e PLA, possiamo consegnare i prototipi entro 5-7 giorni lavorativi dalla ricezione dei file di progettazione. I progetti più complessi possono richiedere fino a 2 settimane.

Sì, possiamo aggiungere parti mobili, integrazione elettronica e ritocchi finali per rendere i prototipi il più funzionali possibile per i test.

Offriamo finitura superficiale, assemblaggio, integrazione hardware e altri trattamenti per far sì che i prototipi sembrino e funzionino come prodotti finiti.

Rispettiamo la tua proprietà intellettuale. Nessuna delle tue information, immagini, file o somiglianze sarà condivisa con terze parti e non sarà utilizzata per scopi pubblicitari, di marketing o promozionali senza la tua esplicita autorizzazione scritta. Se desideri firmare un accordo NDA, contatta il nostro team per ricevere supporto.

Seguiamo lo standard ISO/IATF e garantiamo che rielaboreremo i prodotti o li rimborseremo in caso di problemi di qualità. Il rapporto dimensionale completo, la certificazione del materiale o l'ispezione del primo articolo vengono forniti su richiesta prima dell'effettuazione dell'ordine.