Case Study

One-stop machining service and low-volume production

Case Studies from Different Industry

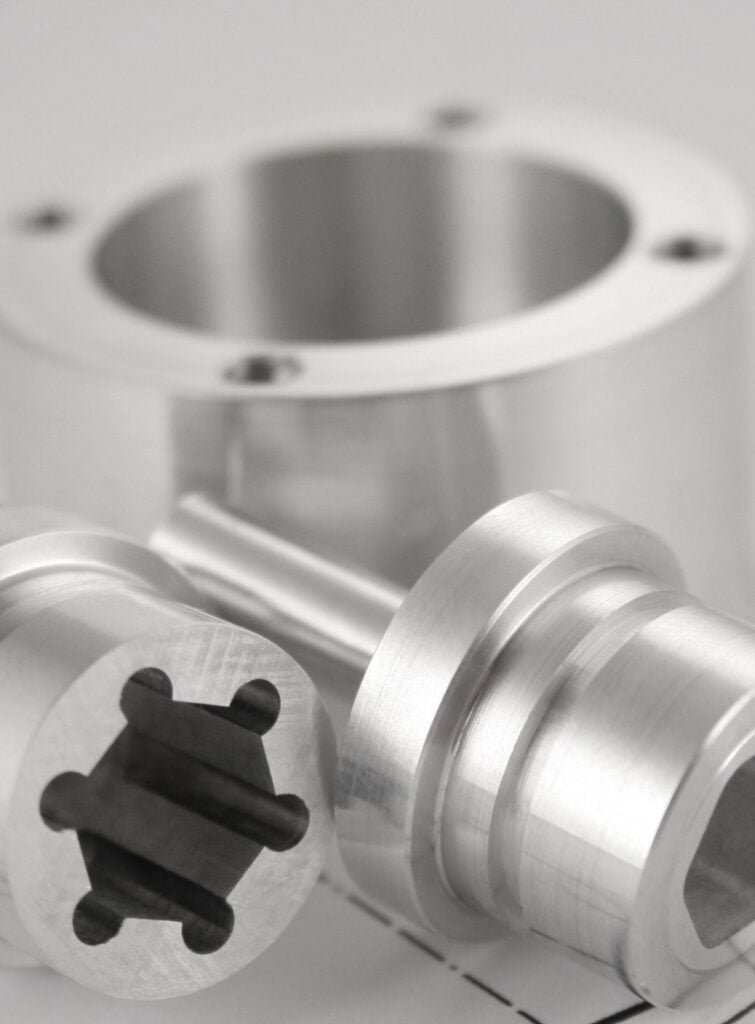

Challenge: Develop a complex, miniature component for a new minimally invasive surgical tool. Solution: Utilized advanced 5-axis CNC milling to create high-precision parts from medical-grade titanium.

Process:

- Collaborated with the client to optimize the design for manufacturability

- Developed a custom fixturing solution for the intricate part

- Implemented rigorous quality control measures to meet FDA standards Results:

- Achieved tolerances of ±0.005mm, exceeding client expectations

- Reduced production time by 30% compared to traditional methods

- Enabled the client to secure a patent and fast-track FDA approval

Challenge: Rapidly iterate on a smart sports watch design before finalizing for mass production. Solution: Employed a combination of SLA 3D printing and vacuum casting for prototyping.

Process:

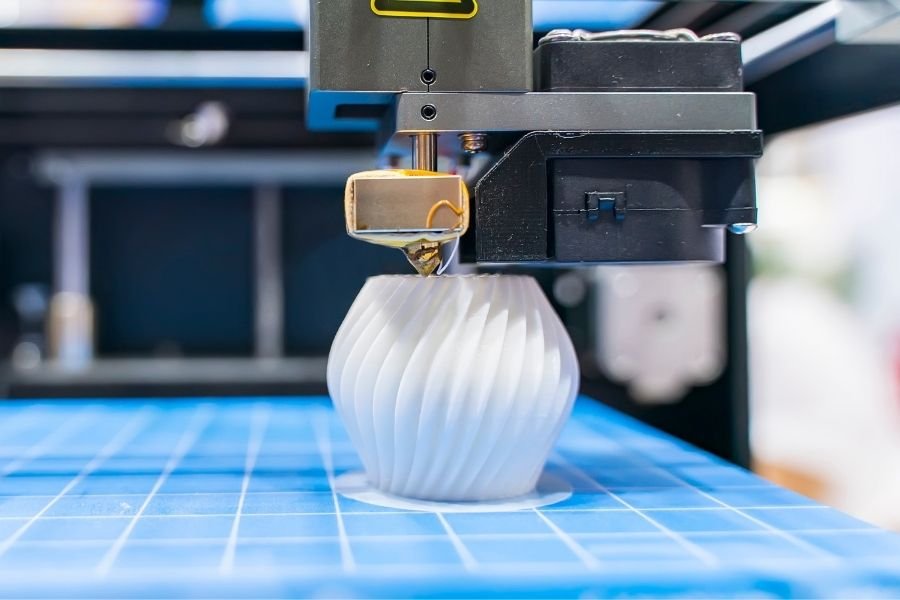

- Used SLA for initial concept models and fit tests

- Created silicone molds for vacuum casting functional prototypes

- Provided surface finishing to achieve production-quality aesthetics Results:

- Produced 20 iterations in just 6 weeks

- Saved the client an estimated $100,000 in tooling costs for design changes

- Helped the client launch 3 months ahead of schedule

Challenge: Transition from low-volume production to meeting growing market demand for a smart thermostat. Solution: Implemented a hybrid approach using CNC machining and injection molding.

Process:

- CNC machined critical components requiring high precision

- Developed rapid tooling for injection molding of housing parts

- Established an assembly line for final product integration Results:

- Scaled production from 500 to 10,000 units per month

- Reduced per-unit cost by 40% through optimized manufacturing

- Maintained consistent quality across increased production volume

Challenge: Create lightweight yet durable control panel housings for a new aircraft model. Solution: Utilized advanced sheet metal fabrication techniques with aerospace-grade aluminum.

Process:

- Collaborated on design to optimize for weight reduction

- Implemented precision laser cutting and CNC bending

- Developed a custom anodizing process for corrosion resistance Results:

- Achieved a 25% weight reduction compared to previous models

- Met stringent aerospace quality standards with zero defects

- Helped the client secure a major contract with a leading airline

Challenge: Produce a market-test run of 5,000 units for a new educational toy before committing to full production tooling. Solution: Developed rapid tooling for injection molding, combined with 3D printed inserts for changeable features.

Process:

- Created aluminum tooling for the main body parts

- 3D printed interchangeable inserts for different product variations

- Established a flexible assembly process for various product configurations Results:

- Delivered 5,000 units in 4 weeks, meeting the client’s launch deadline

- Allowed for mid-run design tweaks based on initial market feedback

- Provided a smooth transition to full production, saving 6 weeks in time-to-market

One-stop Manufacturing Solutions

設計検証のための単一のプロトタイプが必要な場合でも、最終製品の大量生産が必要な場合でも、当社がお手伝いいたします。

ラピッドプロトタイピング

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

少量生産

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

大量生産

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

なんで私達なの

HeyguMake では、機械工学における広範な専門知識に誇りを持っています。当社の専門家チームは、お客様に最高品質の製品とサービスを提供することに専念しています。

専門知識

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

品質保証

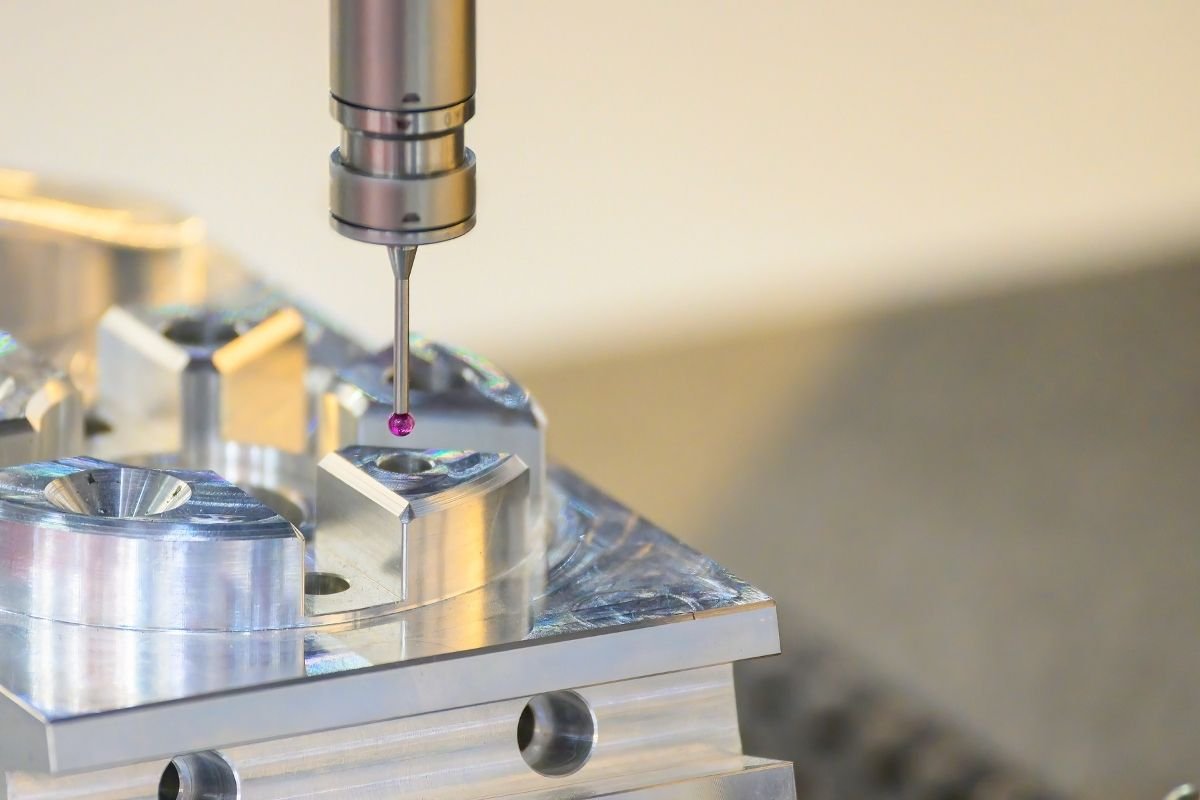

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

よくある質問

当社は、STEP、IGES、STL、OBJ などを含むすべての主要な CAD ファイル タイプをサポートしています。最良の結果を得るには、設計はソリッド モデル形式である必要があります。

ABS や PLA などの標準プラスチックの場合、デザイン ファイルを受け取ってから 5 ~ 7 営業日以内にプロトタイプを納品できます。より複雑なプロジェクトの場合は、最大 2 週間かかる場合があります。

はい、可動部品、電子機器の統合、最後の仕上げを追加して、テスト用に可能な限り機能するプロトタイプを作成できます。

当社は、プロトタイプを完成品のように外観および機能させるために、表面仕上げ、組み立て、ハードウェア統合およびその他の処理を提供します。

私たちはあなたの知的財産を尊重します。あなたの information、画像、ファイル、または肖像はいずれも第三者と共有されることはなく、明示的な書面による許可がない限り、広告、マーケティング、またはプロモーション目的で使用されることはありません。 NDA 契約への署名をご希望の場合は、サポートについて弊社チームにご連絡ください。

当社は ISO/IATF 規格に従い、品質に問題がある場合は製品の再加工または返金を保証します。ご要望に応じて、発注前の全寸法レポート、材料証明書、または最初の製品検査が提供されます。