Quality Assurance

From initial concept to final delivery, our comprehensive services cover every step of the product development process.

Our Quality

At Seamark Prototype, we implement rigorous quality control measures throughout the manufacturing process. Our quality assurance team uses advanced measurement tools and follows strict inspection protocols to ensure that every part meets specified requirements. We can also conduct functional testing as needed.

Our Quality Check Process

ISO 9001:2015 Certified Quality Management System

Our quality management system is certified to ISO 9001:2015 standards, demonstrating our commitment to consistent quality and continuous improvement. This certification ensures that we follow internationally recognized best practices in all our processes, from initial client consultation to final product delivery.

Material Testing

We conduct rigorous material testing to verify that all raw materials meet specified requirements. Our in-house laboratory performs various tests, including tensile strength, hardness, and chemical composition analysis, ensuring that only materials meeting our strict quality criteria are used in production.

Visual Inspection

Our trained inspectors conduct thorough visual examinations of all parts, checking for cosmetic defects, surface finish quality, and overall appearance. This attention to detail ensures that every part not only functions correctly but also meets aesthetic requirements.

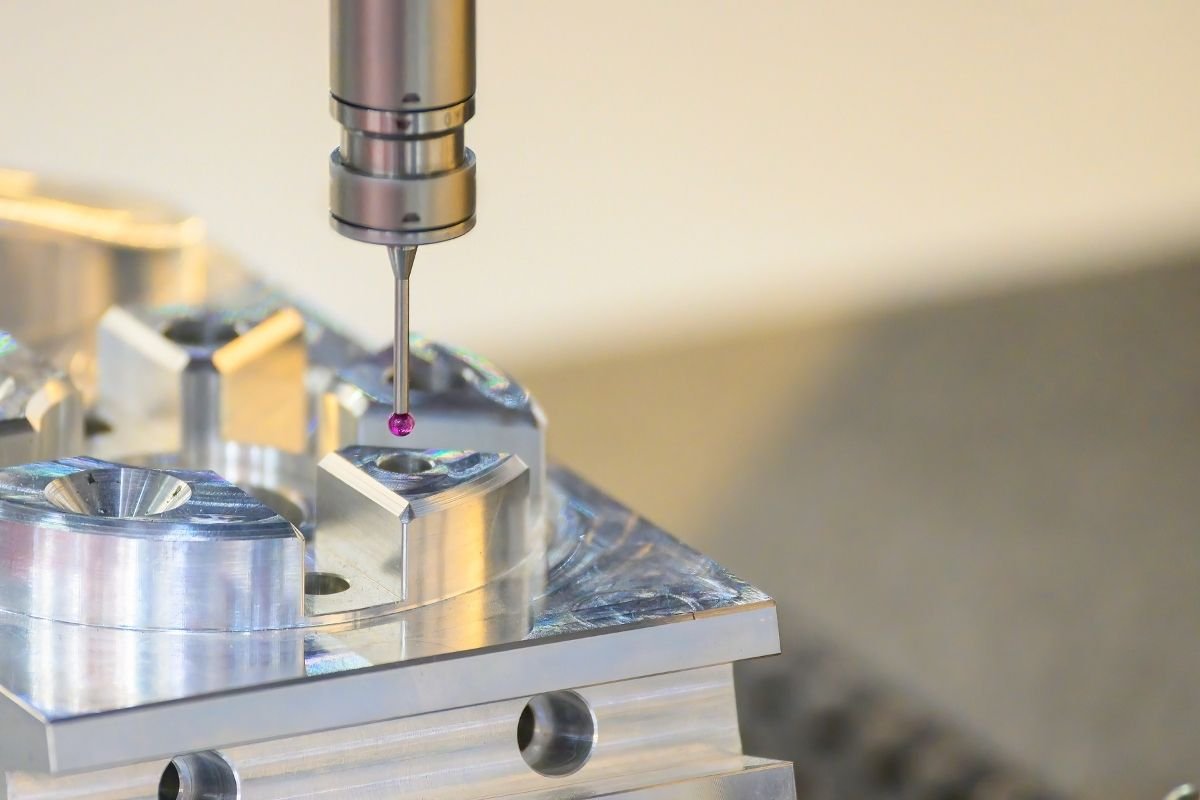

Dimensional Inspection using CMM

Our state-of-the-art Coordinate Measuring Machines (CMM) provide highly accurate 3D measurements of complex parts. This technology allows us to verify critical dimensions with precision, ensuring that all parts meet exact specifications.

First Article Inspection (FAI) Report

For new parts or processes, we conduct comprehensive First Article Inspections. The resulting FAI report provides a detailed analysis of the part’s dimensions, materials, and characteristics, serving as a quality baseline for future production runs.

Why Us

At Seamark Prototype, our multi-faceted approach to quality control ensures that we deliver products of the highest caliber. From raw material to finished part, every step of our process is designed to uphold our commitment to excellence, providing our clients with the confidence that their parts will perform as intended, every time.

Expertise

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

Quality Assurance

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

One-stop Manufacturing Solutions

Whether you require a single prototype for design verification or mass manufacturing of final products, we're here to help

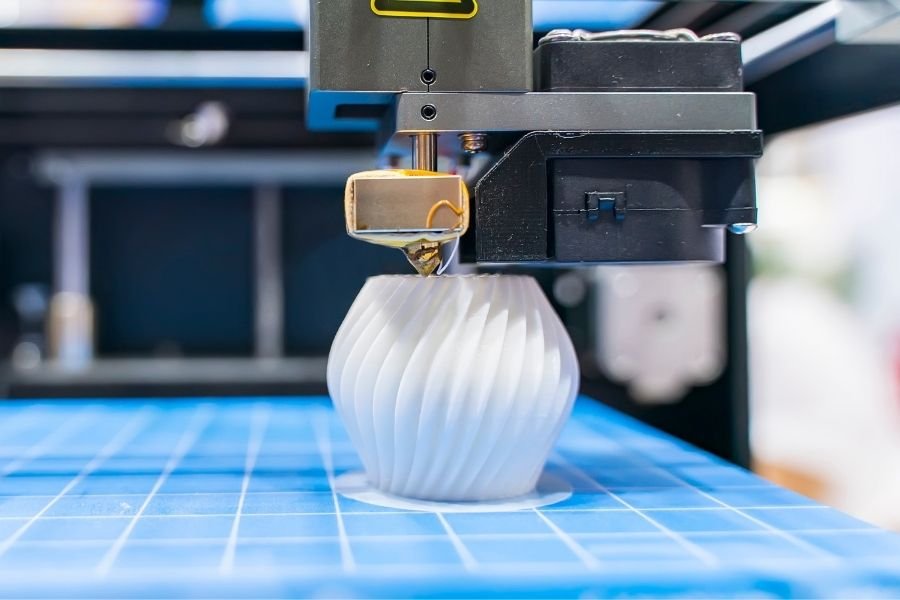

Rapid Prototyping

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

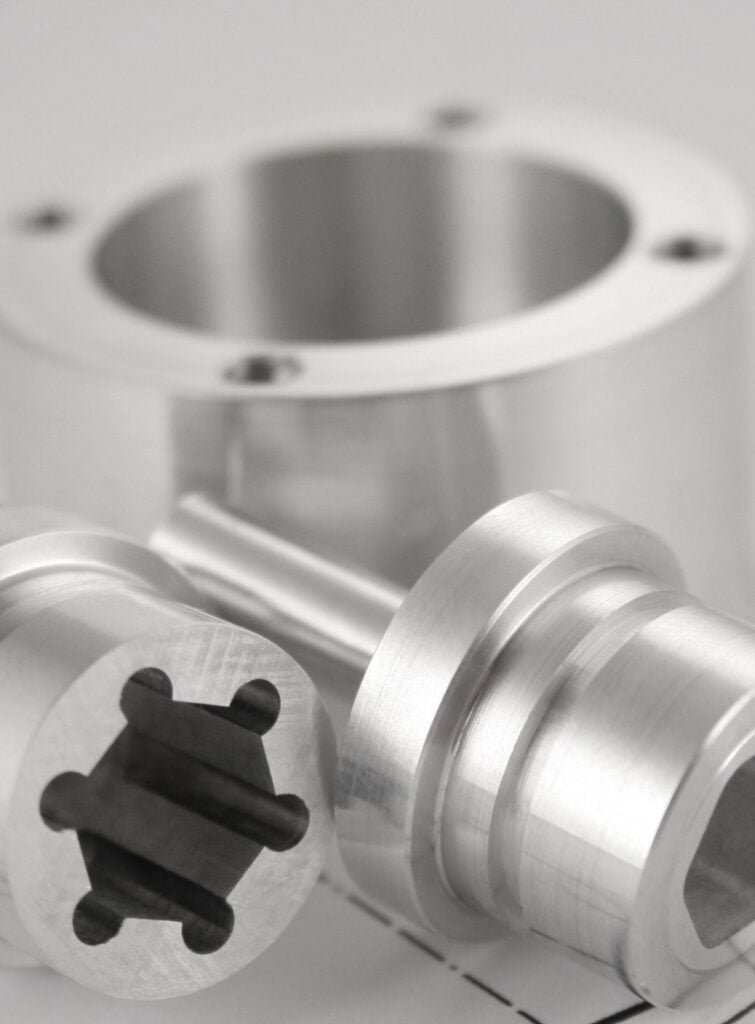

Low-volume Production

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

Mass Production

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Frequently Asked Questions

We support all major CAD file types including STEP, IGES, STL, OBJ etc. Designs should be in solid model format for best results.

For standard plastics like ABS and PLA, we can deliver prototypes within 5-7 business days after receiving your design files. More complex projects may take up to 2 weeks.

Yes, we can add moving parts, electronics integration and finishing touches to make prototypes as functional as possible for testing.

We offer surface finishing, assembly, hardware integration and other treatments to make prototypes look and function like finished products.

We respect your intellectual property. None of your information, images, files or likenesses will be shared with any third party, and it will not be used for any advertising, marketing, or promotional use without your explicit written authorization. If you would like to sign NDA agreement, please contact our team for support.

We follow the ISO/IATF standard and guarantee that we will rework the products or refund them if there are any quality problems. The full-dimensional report, material certification, or first article inspection are provided on request before order placement.