3D Printing Service

From initial concept to final delivery, our comprehensive services cover every step of the product development process.

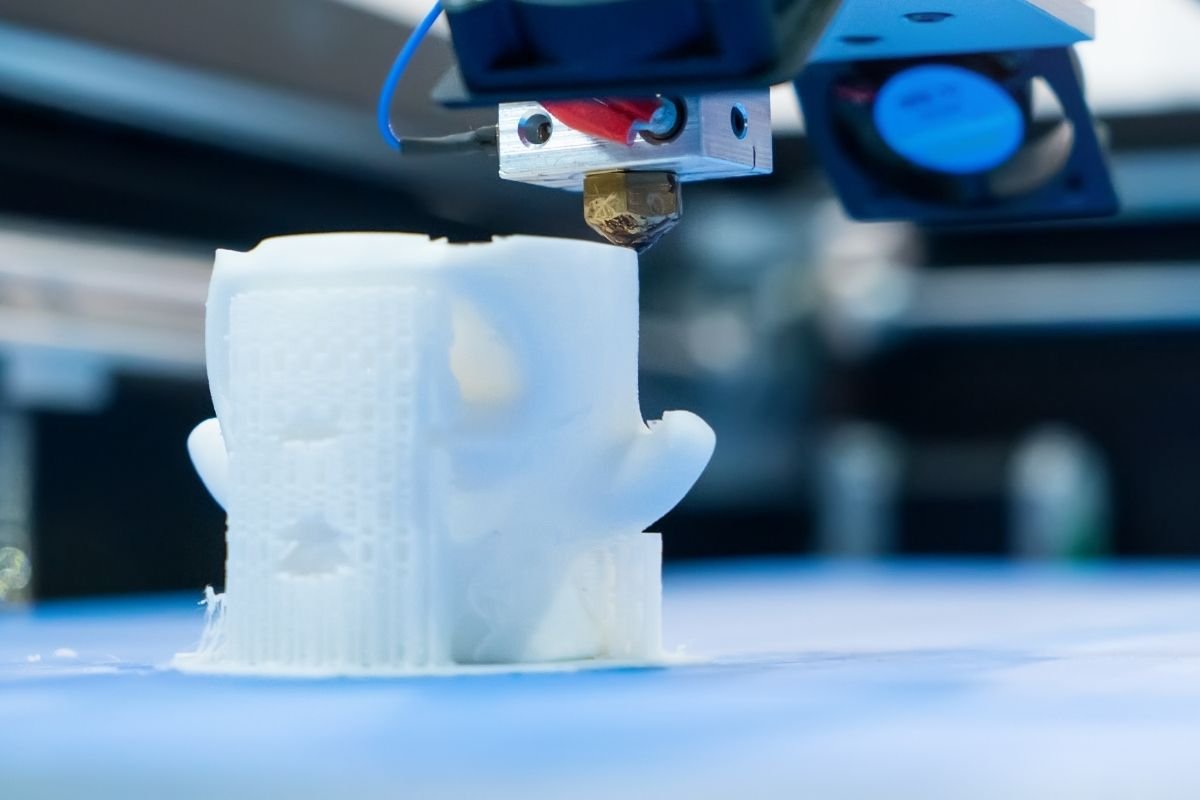

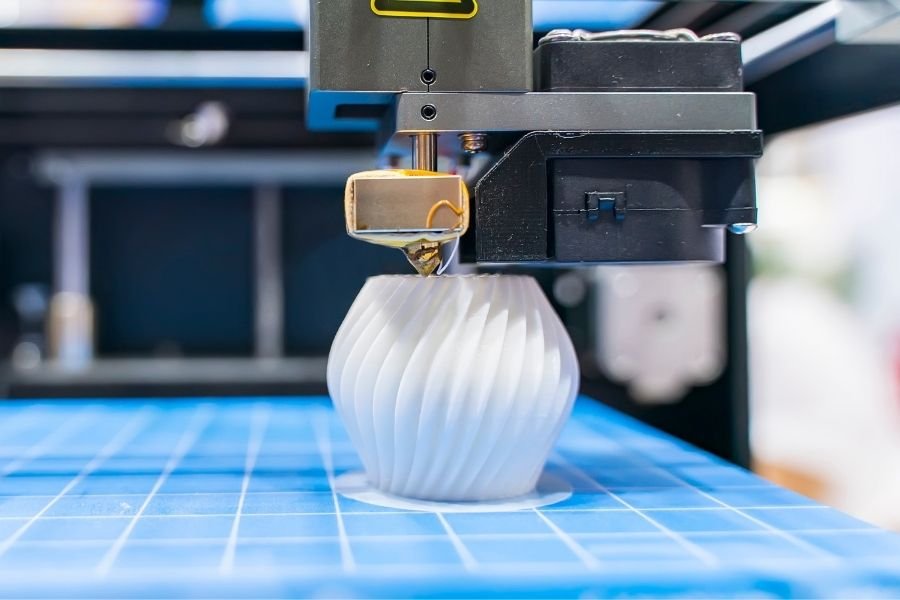

3D Printing

At Seamark Prototype, we offer cutting-edge 3D printing services, providing rapid prototyping and low-volume production solutions. Our advanced 3D printing capabilities allow for the creation of complex geometries, functional prototypes, and end-use parts with a wide range of materials.

Our 3D Printing Processes

- High-resolution printing for smooth surface finishes

- Ideal for detailed prototypes and patterns for casting

- Produces strong, durable parts without support structures

- Excellent for functional prototypes and end-use parts

- Cost-effective for larger parts and quick prototypes

- Wide range of engineering-grade thermoplastics available

- High-speed production of durable, functional parts

- Excellent for complex geometries and assemblies

Materials We Work With

ABS is a plastic material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties, making ABS terpolymer with robust features. ABS has good strength, toughness, and resistance to impact and temperature. It is easily molded and gives a high-quality glossy surface finish. This plastic polymer does not have a specific melting point.

We provide complete ABS machining service and can produce custom ABS parts in various shapes and grades.

Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications. It’s a versatile, durable, flexible material often used as a more affordable alternative to silk, rubber, and latex.

We provide complete Nylon machining service and can produce custom Nylon parts in a variety of shapes and grades.

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Surface Finishing Options

At Seamark Prototype, we understand that the perfect finish can make all the difference in your product’s performance, durability, and market appeal. Our comprehensive finishing services go beyond mere aesthetics, offering functional enhancements that can significantly improve your parts’ properties. From sleek, polished surfaces to robust, corrosion-resistant coatings, we provide a diverse array of finishing options tailored to your specific needs.

Anodizing: This electrochemical process creates a protective oxide layer on the surface of aluminum parts, providing corrosion resistance and a range of color options.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint, which is applied with an evaporating solvent, powder coating is typically applied electrostatically and cured with heat or ultraviolet light.

Bead blasting produces a smooth, matte-textured surface, and sharp edges can be broken and deburred for safe handling. Bead blasting can also improve the mechanical strength, wear resistance and corrosion resistance of parts.

Electroplating is the process of coating an object in a layer of metal using electrodeposition. Electroplating is widely used to improve the surface qualities of metals, such as resistance to abrasion and corrosion, lubricity, reflectivity, and electrical conductivity. Electroplating can also make metals look better.

Polishing is a technique for creating a smooth and shiny surface by rubbing it or applying a chemical treatment. The process creates a surface with significant specular reflection, but it can also reduce diffuse reflection in some materials.

Brushing is a surface treatment process in which an abrasive belt is used to draw marks and lines on the surface of products to achieve a decorative texture.

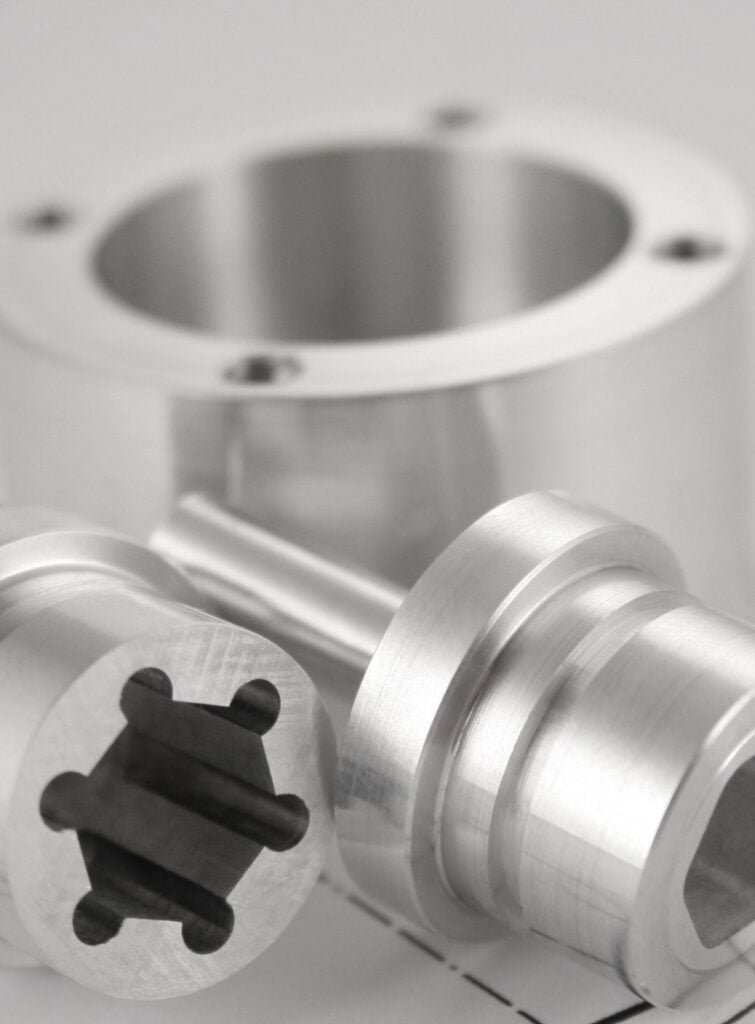

One-stop Manufacturing Solutions

Whether you require a single prototype for design verification or mass manufacturing of final products, we're here to help

Rapid Prototyping

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

Low-volume Production

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

Mass Production

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Why Us

At Seamark, we pride ourselves on our extensive expertise in the mechanical engineering. Our team of professionals is dedicated to providing the highest quality products and services to our customers.

Expertise

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

Quality Assurance

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Frequently Asked Questions

We accept 3D CAD files in STL, STP, STEP, OBJ IGS or IGES format and 2D drawings(jpg, png, gif, bmp, pdf) with dimensional details and specific manufacturing requirements.

We respond within 2 hours after your request. Princing quote will be send within 8 hours.

Yes, master models are used to create silicone molds for vacuum casting and can be made from any rigid solid that can withstand heat up to 100 °C. Models used for CNC machining will be 3D scanned to create a CAD/CAM program for production.

Quality parts less than 1000pcs can be made in as fast as one week if you provide complete 2D and 3D CAD models. More complex parts requiring other special features will take longer. As for shipping, most of our shipments are via air freight, which can take 5-7 days from China to Europe or North America.

We respect your intellectual property. None of your information, images, files or likenesses will be shared with any third party, and it will not be used for any advertising, marketing, or promotional use without your explicit written authorization. If you would like to sign NDA agreement, please contact our team for support.

We follow the ISO/IATF standard and guarantee that we will rework the products or refund them if there are any quality problems. The full-dimensional report, material certification, or first article inspection are provided on request before order placement.