CNC Machining Service

From initial concept to final delivery, our comprehensive services cover every step of the product development process.

CNC Machining

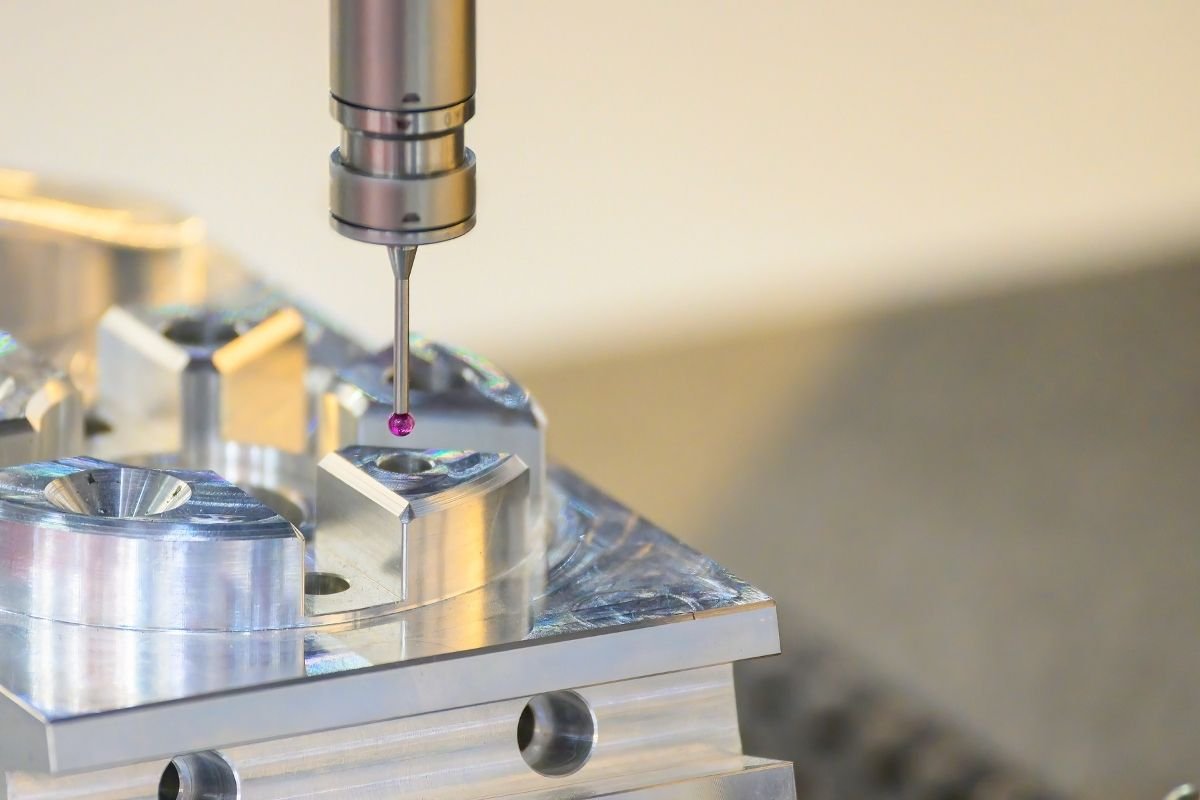

At Seamark Prototype, we offer advanced CNC (Computer Numerical Control) machining services, providing high-precision parts for a wide range of industries. Our state-of-the-art CNC machining center is equipped with the latest technology to deliver exceptional accuracy, consistency, and surface finishes.

Our CNC Machining Processes

- 3-axis milling for standard parts

- 5-axis milling for complex geometries and undercuts

- High-speed milling for rapid material removal

- Micro-milling for intricate, small-scale features

Milling is a process where a rotating cutting tool removes material from the workpiece to create a desired shape or feature. It can be performed on a variety of machine tools, such as:

- Vertical Machining Centers (VMCs): The workpiece is mounted on a table that moves in the X, Y, and Z axes, while the cutting tool moves vertically.

- Horizontal Machining Centers (HMCs): Similar to VMCs but with the spindle oriented horizontally, which can be beneficial for machining larger workpieces or when heavy cutting forces are involved.

- 5-Axis Machining: Allows for complex shapes to be machined by having the cutting tool and workpiece move in five axes, greatly enhancing the range of possible designs.

Milling operations include:

- Face Milling: Used to create flat surfaces.

- Peripheral Milling: The cutting is done by the outer edge of the milling tool.

- End Milling: Uses the end of the tool to create slots, pockets, or profiled surfaces.

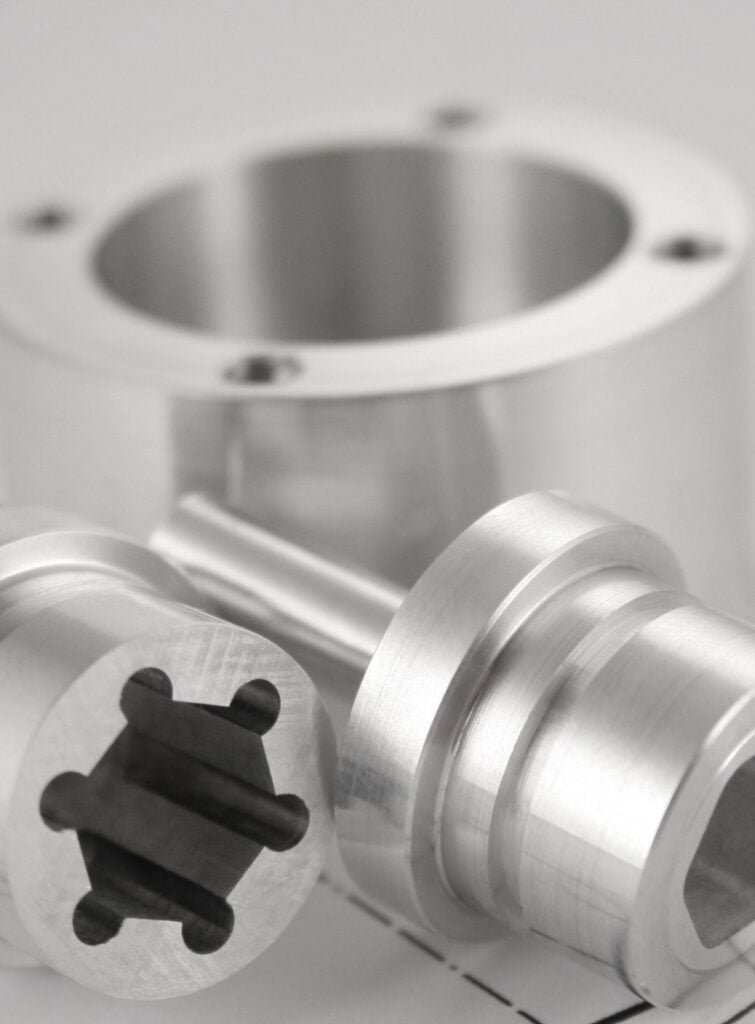

- 2-axis turning for cylindrical parts

- Multi-axis turning with live tooling for complex parts

- Swiss-type lathes for high-precision, small diameter parts

Turning is a subtractive manufacturing process where a workpiece is rotated while a cutting tool moves radially against it to remove material. Common types of turning machines include:

- Lathe Machines: Traditional machines used for turning cylindrical parts.

- CNC Lathes: Computer-controlled lathes that can perform more complex turning operations with high precision.

Turning operations include:

- Straight Turning: Creating straight lengths of material.

- Thread Turning: Cutting threads on the external or internal surface of a cylinder.

- Taper Turning: Creating a conical shape by adjusting the tool’s position relative to the workpiece.

- Wire EDM for intricate cutting of conductive materials

- Sinker EDM for creating complex cavities and shapes

EDM is a non-traditional machining process that uses electrical discharges to erode material from the workpiece. It is particularly useful for hard materials that are difficult to cut with conventional tools. The process involves:

- Die Sinker EDM: Used for creating intricate cavities or dies in conductive materials. The electrode is shaped to match the desired cavity.

- Wire EDM: A thin, continuously fed wire electrode is used to cut through the workpiece, producing very fine and precise cuts.

- Ram EDM: The electrode is shaped like the desired cut and is moved towards the workpiece to erode material.

Key aspects of EDM machining include:

- No Physical Contact: The electrode and workpiece do not physically touch during machining, reducing tool wear.

- High Precision: Capable of achieving very fine tolerances and surface finishes.

- Material Independence: Can machine any conductive material regardless of hardness.

Machining Capabilities:

CNC Machines: 3 axis, 5 axis, 36 self-owned, 100+ equipment from partners.

Max parts dimensions: 1200mm x 800 mm x 800 mm.

Tolerance: Linear dimension: +/-0.01 mm, Hole diameters (not reamed): +/- 0.025 mm, Shaft diameters: +/- 0.025 mm.

Threads and holes: We can adapt to any standard thread size and customized threads.

Min. feature size: The minimum feature size we make is 0.5 mm, depending on the geometry of the product and the materials being used.

Burrs and chamfers: Deburring by default, chamfering according to your requirements.

Surface Finish: The standard finish is 32 Ra or better, you can specify surface finishing options

Materials We Work With

Alloy steel contains trace amounts of one or more alloying elements (other than carbon), such as manganese, silicon, nickel, titanium, copper, chromium, and aluminum. Alloying provides it with unique qualities not present in standard carbon steel. Due to its low cost, wide availability, ease of processing, and superior mechanical rates, alloy steel is ideal for industrial applications. In general, alloy steels are more malleable to heat and mechanical treatment than carbon steels.

We provide complete Alloy Steel CNC machining service and can produce custom Alloy Steel parts in various shapes and grades, including 4130, 4140, 4340, and more.

Mild steel is a type of carbon steel with a low amount of carbon. It is also known as “low carbon steel.” Low carbon means it has very little carbon and other alloying elements to block dislocations in its crystal structure, resulting in less tensile strength than high carbon and alloy steels. Mild steel has good weldability and machinability, making it a popular choice for consumer products.

We provide complete Mild Steel CNC machining service and produce custom Mild Steel parts in a variety of shapes and grades, including Hot and Cold Rolled, Commercial Quality, Galvanized, 1018, 1020, 1026, 1020/1026, CR 1045, HR 1045, 12L14, CR 1215 and more.

Tool steel is a type of carbon alloy steel. It is frequently used to create, modify, or repair hand tools and machine dies. Tool steel is notable for its hardness, abrasion, and deformation resistance. Because steel can retain a cutting edge at extremely high temperatures, it is frequently used to shape other materials via cutting, pressing, coining, or extruding. Because of their abrasion resistance, they are commonly used in the production of injection molds. Tool steel is widely used in dies (stamping or extrusion), cutting, mold production, and impact applications such as hammers (personal or industrial).

We provide complete Tool Steel CNC machining service and can produce custom Tool Steel parts in various shapes and grades, including A2, D2 and O1, and more.

Stainless steel is a steel alloy that is more corrosion resistant than carbon/alloy steel. Stainless steel is an iron alloy that contains at least 10.5 percent chromium. The presence of chromium results in forming a thin chromium oxide film on the surface of the steel, known as a passivation layer. This layer prevents corrosion on the steel surface; the higher the Chromium concentration in the steel, the more excellent the corrosion resistance. Stainless steel is an ideal material for food handling/processing, medical instruments, hardware, appliances, and structural/architectural products.

We provide complete Stainless Steel CNC machining service and can produce custom Stainless Steel parts in various shapes and grades, including 17-4, 303, 304, 316, 416, 440C, and more.

Copper alloys are one of the most versatile metals, and they have beneficial properties like corrosion resistance, high thermal conductivity, and very high electrical conductivity. Copper alloys are excellent for different industries such as electrical, construction, transport, and consumer goods. The final product made from copper includes architectural parts, coinage, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors.

We provide complete Copper CNC machining service and can produce custom Copper parts in a variety of shapes and grades, including Copper C110 and C101.

Brass is a mixture of copper and zinc. Small amounts of zinc elements are frequently added to improve specific properties. Depending on the part of zinc added to the alloy, the color of brass can range from red to yellow. Alloying can increase strength, hardness, electrical and thermal conductivity, corrosion resistance, and color. Brass is also germicidal, which means it can kill microorganisms when they contact it.

Brass is used in various applications and products, including decorative items, architectural parts, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors.

We provide completeBrass CNC machining service and can produce custom Brass parts in various shapes and grades, including Brass C260 and C360.

Aluminum is a silver-colored, low-density metal used in a wide range of commercial applications. Under most conditions, unalloyed aluminum is ductile, has moderate strength, and is highly corrosion-resistant. Appropriate alloying elements (Cu, Mg, Mn, Si, etc.) and subsequent heat/work treatments can significantly strengthen aluminum. Because of its low density and corrosion resistance is widely used in aerospace, transportation, architectural, food, and chemical handling (cookware, pressure vessels, etc.) industries.

We provide complete Aluminum CNC machining service and can produce custom Aluminum parts in a variety of shapes and grades, including 1100, 2011, 2024, 3003, 4017, 5052, 6061, 6063, and 7075.

Titanium alloys are alloys composed of titanium and other chemical elements. Titanium alloys are light in weight, have incredibly high tensile strength and toughness, are extremely corrosion resistant, and withstand extreme temperatures.

Titanium alloys are widely used in military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, high-stress components such as connecting rods on high-end sports cars, and some premium sports equipment and consumer electronics.

We provide complete Titanium CNC machining service and can produce custom Titanium parts in various shapes and grades, including Titanium Grade 1, Titanium Grade 2, and Titanium Grade 5.

Plastics

ABS is a plastic material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties, making ABS terpolymer with robust features. ABS has good strength, toughness, and resistance to impact and temperature. It is easily molded and gives a high-quality glossy surface finish. This plastic polymer does not have a specific melting point.

We provide complete ABS machining service and can produce custom ABS parts in various shapes and grades.

Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications. It’s a versatile, durable, flexible material often used as a more affordable alternative to silk, rubber, and latex.

We provide complete Nylon machining service and can produce custom Nylon parts in a variety of shapes and grades.

Polycarbonate(PC) is a thermoplastic polymer containing carbonate groups in their chemical structures. Polycarbonate has good stiffness and thermal resistance due to its molecular structure and reasonably high viscosity. Polycarbonates can be molded and thermoformed with great ease, making them a popular choice for a wide range of products.

We provide complete polycarbonate machining service and can produce custom polycarbonate parts in a variety of shapes and grades.

Polyethylene (PE) is generally divided into multiple groups based on density. These include low-density polyethylene (or LDPE), medium density polyethylene (MDPE), high-density polyethylene (HDPE), and ultra-high molecular weight polyethylene (UHMWPE or UHMW). The higher the density, the higher the tensile and flexural strength, chemical and abrasion resistance, and surface hardness.

We provide complete Polyethylene machining service and can produce custom Polyethylene parts in a variety of shapes and grades.

PET(Polyethylene Terephthalate) or polyester is a semi-crystalline resin with a good balance of strength, stiffness, toughness, a natural high gloss finish, excellent chemical resistance, and good dielectric properties. PET is approved as safe for contact with foods and beverages worldwide; PET is sustainable, completely recyclable, and they are the most recycled plastic. PET is commonly used in Plastic components in electrical products, Electrical encapsulation or insulation, Electrical insulation polymers, Connectors for electrical, Packaging or containers for consumables and food, and Appliances.

We provide complete PET injection molding service and can produce custom PET parts in various shapes and grades.

Acrylic(PMMA) is a glass-like plastic, their excellent weatherability, good resistance to fading caused by UV and fluorescent lighting, and high resistance to scratching, durability, and natural transparency mak it a good material choice for food storage containers, refrigerator drawers,automotive and consumer products. Acrylics are also well-suited to overmolding and other specialized injection molding processes.

We provide complete Acrylic injection molding service and can produce custom Acrylic parts in various shapes and grades.

Polyoxymethylene (POM), also known as Delrin® or Acetal, is a thermoplastic engineered material used to make parts that require increased stiffness, low friction versatility, and more excellent dimensional stability. POM has high tensile strength, wear resistance, creep and warp resistance, and overall toughness and durability. POM is widely used in manufacturing gears, bearings, conveyor parts, automotive parts, sporting equipment, electrical components, sliding and guiding parts, and so on.

We provide complete POM/Delrin®/Acetal injection molding service and can produce custom POM parts in various shapes and grades. LEADRP will work with you to produce injection molded Delrin® parts that meet the exact specifications of your project.

Polypropylene (PP) is a polyolefin or saturated polymer, like polyethylene (PE) and polybutene (PB). PP is one of the most versatile polymers with good chemical resistance, fatigue resistance, better temperature resistance, and lower density than HDPE.

PP is widely made for buckets, bowls, crates, toys, medical components, washing machine drums, battery cases, and bottle caps. PP can be elastomer modified for bumpers and talc-filled for added stiffness at high temperatures.

Polytetrafluoroethylene (PTFE), also known as Teflon®, is a synthetic tetrafluoroethylene with numerous applications. PTFE has high thermal stability, good chemical resistance, and high-temperature resistance.

PTFE products also have excellent sliding properties, electrical resistance, and a nonstick surface. PTFE can be reinforced with glass fiber, carbon, or bronze additives to improve mechanical properties. Due to its structure, PTFE is frequently formed into semi-finished products using compression molding and then machined with cutting/machining tools.

PEEK is a family of high-performance thermoplastics. The name PEEK is derived from the words polyether ether ketone.

PEEK is a engineering plastic used for a wide range of applications where it needs to be strong and tough. It has good chemical resistance and can withstand high temperatures up to 260°C.

PEEK has excellent mechanical properties, making it suitable for applications such as medical implants, automotive components, and even aeronautical parts. PEEK is also used in electronic components such as connectors and insulators.

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Surface Finishing Options

At Seamark Prototype, we understand that the perfect finish can make all the difference in your product’s performance, durability, and market appeal. Our comprehensive finishing services go beyond mere aesthetics, offering functional enhancements that can significantly improve your parts’ properties. From sleek, polished surfaces to robust, corrosion-resistant coatings, we provide a diverse array of finishing options tailored to your specific needs.

Anodizing: This electrochemical process creates a protective oxide layer on the surface of aluminum parts, providing corrosion resistance and a range of color options.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint, which is applied with an evaporating solvent, powder coating is typically applied electrostatically and cured with heat or ultraviolet light.

Bead blasting produces a smooth, matte-textured surface, and sharp edges can be broken and deburred for safe handling. Bead blasting can also improve the mechanical strength, wear resistance and corrosion resistance of parts.

Electroplating is the process of coating an object in a layer of metal using electrodeposition. Electroplating is widely used to improve the surface qualities of metals, such as resistance to abrasion and corrosion, lubricity, reflectivity, and electrical conductivity. Electroplating can also make metals look better.

Polishing is a technique for creating a smooth and shiny surface by rubbing it or applying a chemical treatment. The process creates a surface with significant specular reflection, but it can also reduce diffuse reflection in some materials.

Brushing is a surface treatment process in which an abrasive belt is used to draw marks and lines on the surface of products to achieve a decorative texture.

Why Us

Our diverse capabilities in CNC milling, 3D printing, vacuum casting, sheet metal fabrication, and more allow us to select the best manufacturing method for each component of your project. This versatility ensures optimal quality, cost-effectiveness, and efficiency throughout your product’s development cycle.

Expertise

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

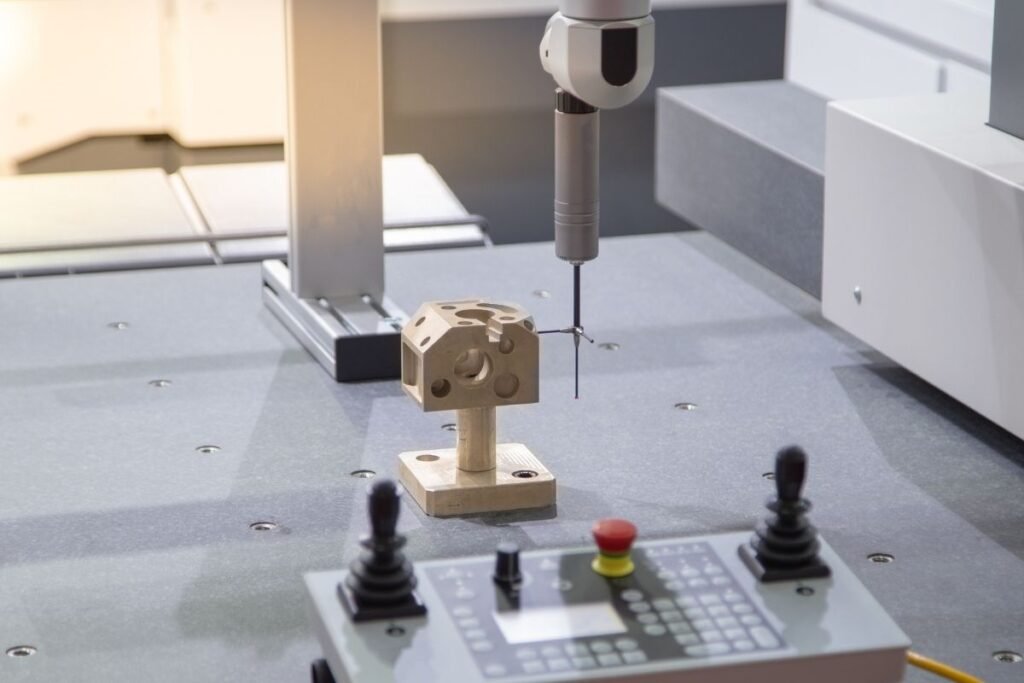

Quality Assurance

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Frequently Asked Questions

Absolutely. We provide a range of post-processing services includiWe accept most common 3D CAD file formats, including:

- STL (preferred)

- OBJ

- STEP

- IGES

- Solidworks files (.sldprt, .sldasm) If you have a different file format, please contact us, and we’ll do our best to accommodate your needs.

ng surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.

Turnaround times vary depending on the complexity of the project and the manufacturing method used. For simple projects, we can often deliver within 3-5 business days. More complex projects may take 1-2 weeks. We recommend contacting us directly for a more accurate estimate based on your specific requirements.

While we primarily work with customer-provided 3D models, we do offer basic design assistance and can help refine your existing designs for manufacturability. For more extensive design work, we can recommend trusted partners or discuss your needs on a case-by-case basis.

We work with a wide range of materials including various plastics, metals, and composites. Our capabilities include ABS, PLA, and resin for 3D printing; aluminum, steel, and other metals for CNC milling and sheet metal work; and a variety of resins for vacuum casting. We can discuss specific material requirements for your project.

Yes, we specialize in both rapid prototyping and low-volume manufacturing. Our services are scalable, allowing us to produce anywhere from a single prototype to several hundred units, depending on your needs and the manufacturing method used.

Absolutely. We provide a range of post-processing services including surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.