Injection Molding Service

From initial concept to final delivery, our comprehensive services cover every step of the product development process.

Injection Molding Service

Seamark Prototype offers comprehensive injection molding services, providing high-quality, cost-effective solutions for both prototyping and mass production. Our advanced injection molding capabilities allow us to produce complex plastic parts with excellent repeatability and precision.

Our Injection Molding Processes

This is the most common form of injection molding where the material, typically plastic or wax, is melted and then injected into a mold cavity. The mold is then cooled, allowing the material to solidify into the desired shape. Once solidified, the mold opens, and the part is ejected.

- Process: Involves a single injection of material into the mold.

- Applications: Suitable for a wide range of plastic parts, from simple to complex geometries.

Also known as two-component or multi-shot molding, this process involves injecting two different materials into the mold in sequence to create a single part with different properties or colors.

- Process: Uses two separate injection units to inject different materials.

- Applications: Useful for parts that require different material properties, such as soft-touch grips on hard plastic handles.

In insert molding, a pre-formed insert (usually metal or hard plastic) is placed into the mold before the molten material is injected around it. This creates a part that combines the insert material with the molded material.

- Process: Involves placing an insert into the mold before injection.

- Benefits: Allows for the combination of different materials and can provide structural reinforcement.

Overmolding is similar to insert molding but involves molding one material over another in a two-step process. The first material is molded and then partially overmolded with a second material to create a multi-layered part.

- Process: Involves molding a base part and then overmolding it with a second material.

- Applications: Commonly used for soft-touch coatings on electronic devices or combining hard and soft materials for functional purposes.

Injection Molding Capabilities:

- Clamping force range: 15 to 500 tons

- Maximum part size: up to 1000mm in largest dimension

- Minimum wall thickness: down to 0.4mm

- Ability to mold complex geometries, including undercuts and internal features

Materials We Work With

Plastics

ABS is a plastic material with three main ingredients: acrylonitrile, butadiene, and styrene. Each of these monomers imparts specific properties, making ABS terpolymer with robust features. ABS has good strength, toughness, and resistance to impact and temperature. It is easily molded and gives a high-quality glossy surface finish. This plastic polymer does not have a specific melting point.

We provide complete ABS machining service and can produce custom ABS parts in various shapes and grades.

Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications. It’s a versatile, durable, flexible material often used as a more affordable alternative to silk, rubber, and latex.

We provide complete Nylon machining service and can produce custom Nylon parts in a variety of shapes and grades.

Polycarbonate(PC) is a thermoplastic polymer containing carbonate groups in their chemical structures. Polycarbonate has good stiffness and thermal resistance due to its molecular structure and reasonably high viscosity. Polycarbonates can be molded and thermoformed with great ease, making them a popular choice for a wide range of products.

We provide complete polycarbonate machining service and can produce custom polycarbonate parts in a variety of shapes and grades.

Polyethylene (PE) is generally divided into multiple groups based on density. These include low-density polyethylene (or LDPE), medium density polyethylene (MDPE), high-density polyethylene (HDPE), and ultra-high molecular weight polyethylene (UHMWPE or UHMW). The higher the density, the higher the tensile and flexural strength, chemical and abrasion resistance, and surface hardness.

We provide complete Polyethylene machining service and can produce custom Polyethylene parts in a variety of shapes and grades.

PET(Polyethylene Terephthalate) or polyester is a semi-crystalline resin with a good balance of strength, stiffness, toughness, a natural high gloss finish, excellent chemical resistance, and good dielectric properties. PET is approved as safe for contact with foods and beverages worldwide; PET is sustainable, completely recyclable, and they are the most recycled plastic. PET is commonly used in Plastic components in electrical products, Electrical encapsulation or insulation, Electrical insulation polymers, Connectors for electrical, Packaging or containers for consumables and food, and Appliances.

We provide complete PET injection molding service and can produce custom PET parts in various shapes and grades.

Acrylic(PMMA) is a glass-like plastic, their excellent weatherability, good resistance to fading caused by UV and fluorescent lighting, and high resistance to scratching, durability, and natural transparency mak it a good material choice for food storage containers, refrigerator drawers,automotive and consumer products. Acrylics are also well-suited to overmolding and other specialized injection molding processes.

We provide complete Acrylic injection molding service and can produce custom Acrylic parts in various shapes and grades.

Polyoxymethylene (POM), also known as Delrin® or Acetal, is a thermoplastic engineered material used to make parts that require increased stiffness, low friction versatility, and more excellent dimensional stability. POM has high tensile strength, wear resistance, creep and warp resistance, and overall toughness and durability. POM is widely used in manufacturing gears, bearings, conveyor parts, automotive parts, sporting equipment, electrical components, sliding and guiding parts, and so on.

We provide complete POM/Delrin®/Acetal injection molding service and can produce custom POM parts in various shapes and grades. LEADRP will work with you to produce injection molded Delrin® parts that meet the exact specifications of your project.

Polypropylene (PP) is a polyolefin or saturated polymer, like polyethylene (PE) and polybutene (PB). PP is one of the most versatile polymers with good chemical resistance, fatigue resistance, better temperature resistance, and lower density than HDPE.

PP is widely made for buckets, bowls, crates, toys, medical components, washing machine drums, battery cases, and bottle caps. PP can be elastomer modified for bumpers and talc-filled for added stiffness at high temperatures.

Polytetrafluoroethylene (PTFE), also known as Teflon®, is a synthetic tetrafluoroethylene with numerous applications. PTFE has high thermal stability, good chemical resistance, and high-temperature resistance.

PTFE products also have excellent sliding properties, electrical resistance, and a nonstick surface. PTFE can be reinforced with glass fiber, carbon, or bronze additives to improve mechanical properties. Due to its structure, PTFE is frequently formed into semi-finished products using compression molding and then machined with cutting/machining tools.

PEEK is a family of high-performance thermoplastics. The name PEEK is derived from the words polyether ether ketone.

PEEK is a engineering plastic used for a wide range of applications where it needs to be strong and tough. It has good chemical resistance and can withstand high temperatures up to 260°C.

PEEK has excellent mechanical properties, making it suitable for applications such as medical implants, automotive components, and even aeronautical parts. PEEK is also used in electronic components such as connectors and insulators.

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Surface Finishing Options

At Seamark Prototype, we understand that the perfect finish can make all the difference in your product’s performance, durability, and market appeal. Our comprehensive finishing services go beyond mere aesthetics, offering functional enhancements that can significantly improve your parts’ properties. From sleek, polished surfaces to robust, corrosion-resistant coatings, we provide a diverse array of finishing options tailored to your specific needs.

Anodizing: This electrochemical process creates a protective oxide layer on the surface of aluminum parts, providing corrosion resistance and a range of color options.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint, which is applied with an evaporating solvent, powder coating is typically applied electrostatically and cured with heat or ultraviolet light.

Bead blasting produces a smooth, matte-textured surface, and sharp edges can be broken and deburred for safe handling. Bead blasting can also improve the mechanical strength, wear resistance and corrosion resistance of parts.

Electroplating is the process of coating an object in a layer of metal using electrodeposition. Electroplating is widely used to improve the surface qualities of metals, such as resistance to abrasion and corrosion, lubricity, reflectivity, and electrical conductivity. Electroplating can also make metals look better.

Polishing is a technique for creating a smooth and shiny surface by rubbing it or applying a chemical treatment. The process creates a surface with significant specular reflection, but it can also reduce diffuse reflection in some materials.

Brushing is a surface treatment process in which an abrasive belt is used to draw marks and lines on the surface of products to achieve a decorative texture.

One-stop Manufacturing Solutions

Whether you require a single prototype for design verification or mass manufacturing of final products, we're here to help

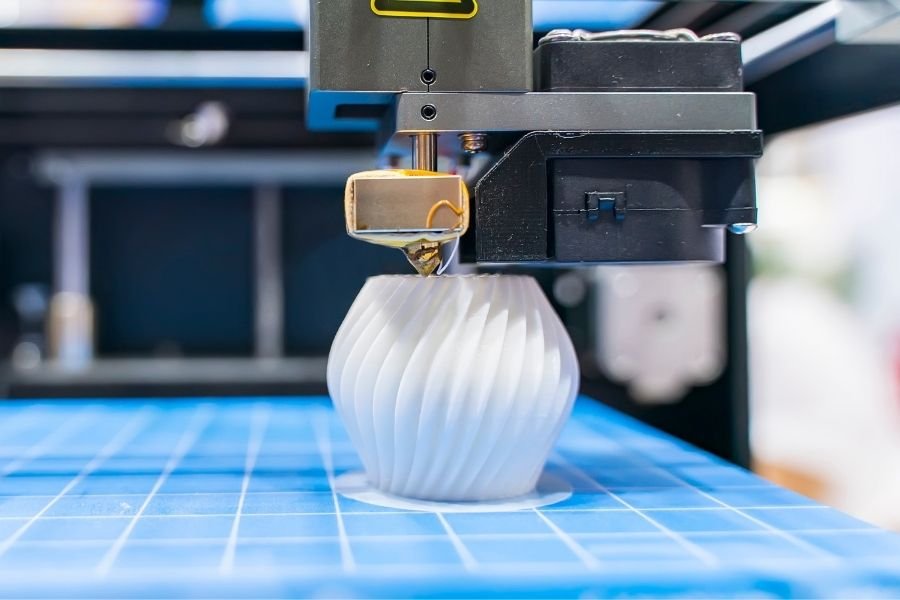

Rapid Prototyping

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

Low-volume Production

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

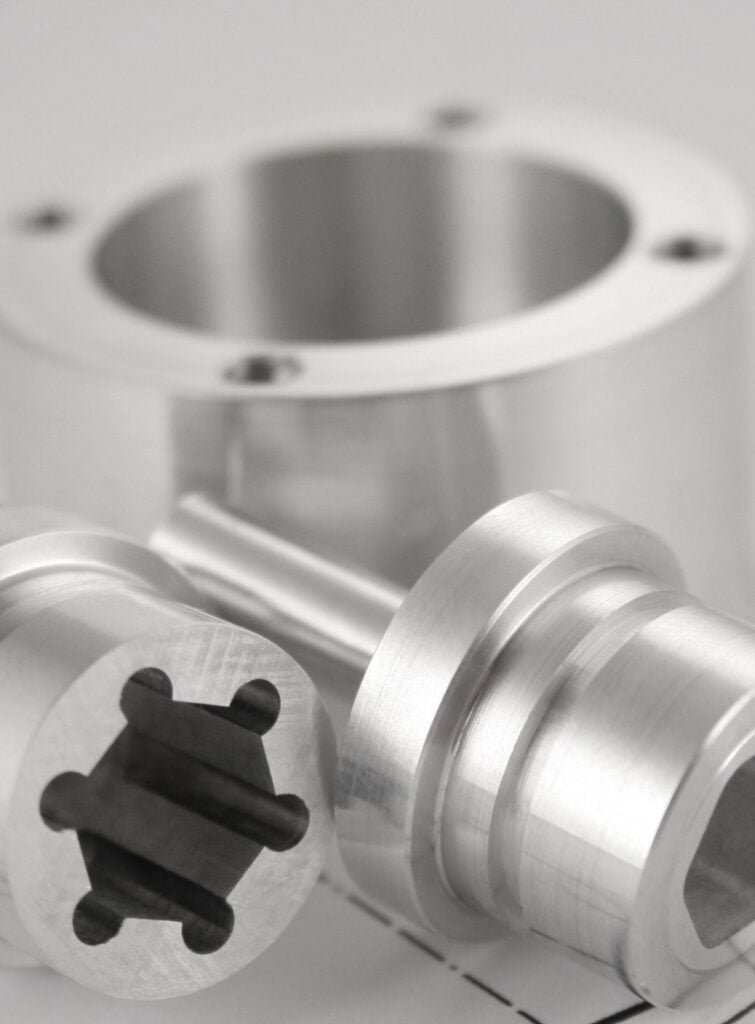

Mass Production

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Why Us

At Seamark, we pride ourselves on our extensive expertise in the mechanical engineering. Our team of professionals is dedicated to providing the highest quality products and services to our customers.

Expertise

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

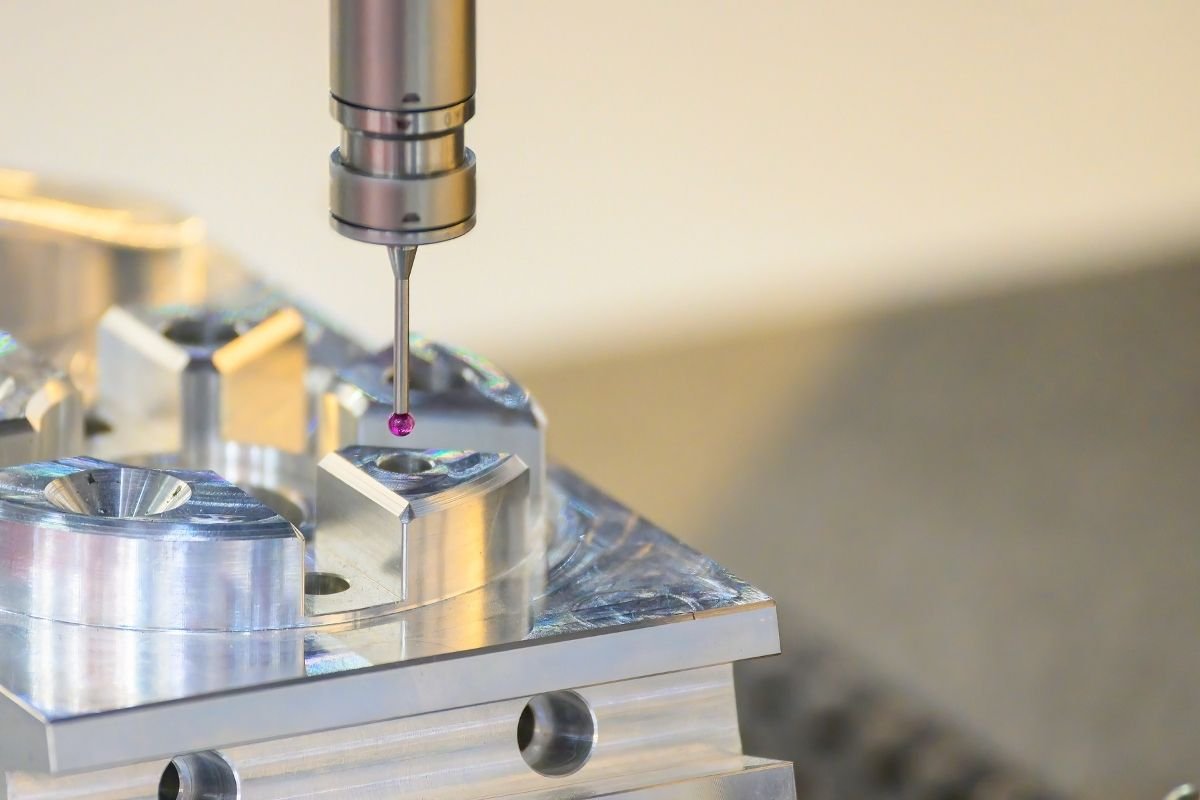

Quality Assurance

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Frequently Asked Questions

Absolutely. We provide a range of post-processing services includiWe accept most common 3D CAD file formats, including:

- STL (preferred)

- OBJ

- STEP

- IGES

- Solidworks files (.sldprt, .sldasm) If you have a different file format, please contact us, and we’ll do our best to accommodate your needs.

ng surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.

Turnaround times vary depending on the complexity of the project and the manufacturing method used. For simple projects, we can often deliver within 3-5 business days. More complex projects may take 1-2 weeks. We recommend contacting us directly for a more accurate estimate based on your specific requirements.

While we primarily work with customer-provided 3D models, we do offer basic design assistance and can help refine your existing designs for manufacturability. For more extensive design work, we can recommend trusted partners or discuss your needs on a case-by-case basis.

We work with a wide range of materials including various plastics, metals, and composites. Our capabilities include ABS, PLA, and resin for 3D printing; aluminum, steel, and other metals for CNC milling and sheet metal work; and a variety of resins for vacuum casting. We can discuss specific material requirements for your project.

Yes, we specialize in both rapid prototyping and low-volume manufacturing. Our services are scalable, allowing us to produce anywhere from a single prototype to several hundred units, depending on your needs and the manufacturing method used.

Absolutely. We provide a range of post-processing services including surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.