Sheet Metal Fabrication Service

From initial concept to final products, our comprehensive services cover every step of the product development process.

Sheet Metal Fabrication

Seamark Prototype offers comprehensive sheet metal fabrication services, leveraging advanced technology and skilled craftsmanship to deliver high-quality, precision-engineered metal components. Our state-of-the-art facility is equipped to handle a wide range of materials and project requirements, from simple brackets to complex assemblies.

Our Sheet Metal Fabrication Processes

Cutting is the initial stage where the sheet metal is cut into specific shapes and sizes. The process can be manual or automated, depending on the complexity and volume of the job. Common cutting methods include:

- Shearing: Uses a mechanical shearing machine to cut straight lines with a blade.

- Laser Cutting: Employs a high-powered laser to cut intricate designs with high precision.

- Plasma Cutting: Utilizes a superheated jet of ionized gas to cut through metal, suitable for thicker materials.

- Water Jet Cutting: A stream of high-pressure water mixed with an abrasive garnet is used for cutting without heat-affected zones.

- Punching: Involves a punch and die to create holes or cutouts in the sheet metal.

Bending is the process of shaping the metal into a desired form by applying force along a line. This can be achieved through:

- Press Brakes: Mechanical presses that bend the metal by applying pressure along a die.

- CNC Bending: Computer-numerically controlled machines that offer high precision and repeatability in bending complex shapes.

- Air Bending: A technique that uses air pressure to bend the metal, often used for lighter materials.

Punching is the process of creating holes or slots in the sheet metal. It is typically done using:

- Stamping Presses: Large presses that use a punch and die to create precise holes or shapes.

- CNC Punching: Automated systems that offer flexibility in creating various hole patterns and sizes.

- Nesting: A technique where the sheet is positioned to minimize waste when punching multiple holes.

Welding is the process of joining metal pieces together by melting the base materials and adding filler material if necessary. Common welding methods in sheet metal fabrication include:

- MIG (Metal Inert Gas) Welding: Uses a continuously fed wire electrode and an inert shielding gas to create a stable arc for welding.

- TIG (Tungsten Inert Gas) Welding: Offers high precision with a non-consumable tungsten electrode and a shielding gas.

- Spot Welding: Creates localized焊 welds at specific points, often used for lighter gauge materials.

- Laser Welding: Utilizes a laser beam to join materials with high precision and minimal heat-affected zone.

Thickness Range:

We can work with sheet metal ranging from 0.5mm to 20mm thickness, depending on the material and specific requirements of the project.

One-stop Manufacturing Solutions

Whether you require a single prototype for design verification or mass manufacturing of final products, we're here to help

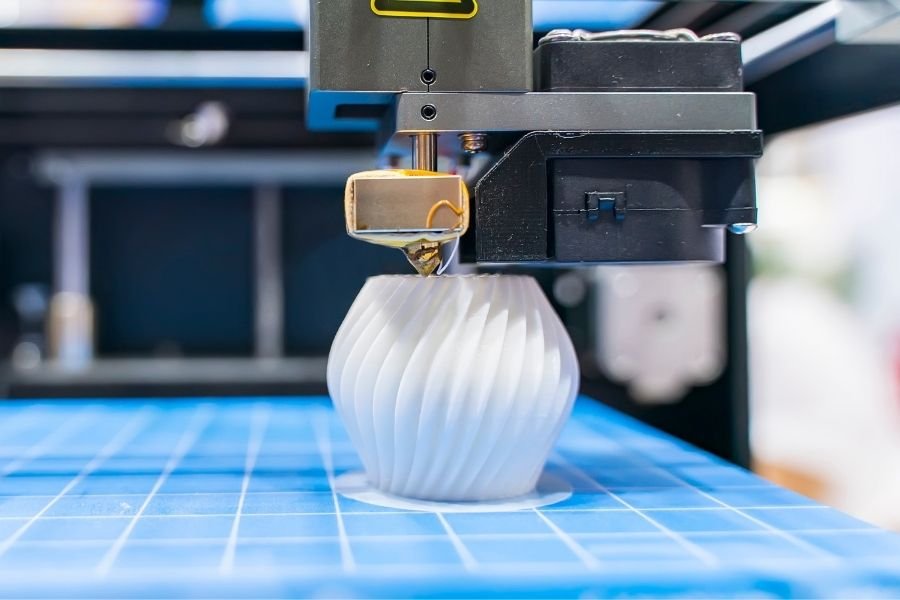

Rapid Prototyping

Our rapid prototyping capabilities enable you to validate designs, perform functional testing, and iterate quickly. With fast turnaround times and expert guidance, we help you refine your product concept efficiently, accelerating your development cycle and reducing time-to-market.

Low-volume Production

Our low-volume production services bridge the gap between prototyping and mass manufacturing. Ideal for market testing, product launches, or niche markets, we offer flexible production runs typically ranging from 10 to 10,000 units.

Mass Production

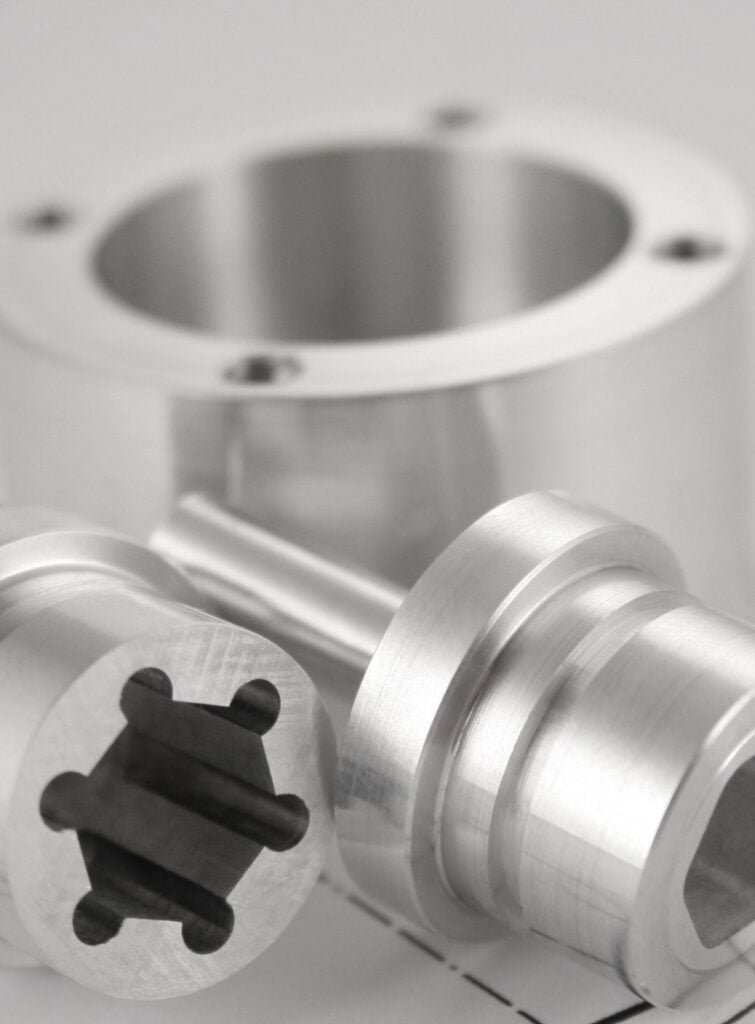

We use injection molding, high-speed CNC machining, and automated assembly lines to produce large quantities of your product. Our expert team optimizes your design for manufacturability, develops robust tooling, and implements stringent quality control measures to ensure consistent output.

Materials We Work With

Galvanized steel is a type of steel that has been coated with a layer of zinc. This zinc coating is applied to protect the steel from corrosion, which is a common issue with ordinary steel when exposed to the elements.

This material is indispensable across various industries due to its strength, corrosion resistance, and versatility. The fabrication techniques for galvanized steel sheets include butting flat sheets, bending parts, drilling holes, adding slots, and notching, enabling the creation of complex galvanized steel parts

Alloy steel contains trace amounts of one or more alloying elements (other than carbon), such as manganese, silicon, nickel, titanium, copper, chromium, and aluminum. Alloying provides it with unique qualities not present in standard carbon steel. Due to its low cost, wide availability, ease of processing, and superior mechanical rates, alloy steel is ideal for industrial applications. In general, alloy steels are more malleable to heat and mechanical treatment than carbon steels.

We provide complete Alloy Steel CNC machining service and can produce custom Alloy Steel parts in various shapes and grades, including 4130, 4140, 4340, and more.

Mild steel is a type of carbon steel with a low amount of carbon. It is also known as “low carbon steel.” Low carbon means it has very little carbon and other alloying elements to block dislocations in its crystal structure, resulting in less tensile strength than high carbon and alloy steels. Mild steel has good weldability and machinability, making it a popular choice for consumer products.

We provide complete Mild Steel CNC machining service and produce custom Mild Steel parts in a variety of shapes and grades, including Hot and Cold Rolled, Commercial Quality, Galvanized, 1018, 1020, 1026, 1020/1026, CR 1045, HR 1045, 12L14, CR 1215 and more.

Stainless steel is a steel alloy that is more corrosion resistant than carbon/alloy steel. Stainless steel is an iron alloy that contains at least 10.5 percent chromium. The presence of chromium results in forming a thin chromium oxide film on the surface of the steel, known as a passivation layer. This layer prevents corrosion on the steel surface; the higher the Chromium concentration in the steel, the more excellent the corrosion resistance. Stainless steel is an ideal material for food handling/processing, medical instruments, hardware, appliances, and structural/architectural products.

We provide complete Stainless Steel CNC machining service and can produce custom Stainless Steel parts in various shapes and grades, including 17-4, 303, 304, 316, 416, 440C, and more.

Copper alloys are one of the most versatile metals, and they have beneficial properties like corrosion resistance, high thermal conductivity, and very high electrical conductivity. Copper alloys are excellent for different industries such as electrical, construction, transport, and consumer goods. The final product made from copper includes architectural parts, coinage, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors.

We provide complete Copper CNC machining service and can produce custom Copper parts in a variety of shapes and grades, including Copper C110 and C101.

Brass is a mixture of copper and zinc. Small amounts of zinc elements are frequently added to improve specific properties. Depending on the part of zinc added to the alloy, the color of brass can range from red to yellow. Alloying can increase strength, hardness, electrical and thermal conductivity, corrosion resistance, and color. Brass is also germicidal, which means it can kill microorganisms when they contact it.

Brass is used in various applications and products, including decorative items, architectural parts, condenser/heat exchangers, plumbing, radiator cores, musical instruments, locks, fasteners, hinges, ammunition components, and electrical connectors.

We provide completeBrass CNC machining service and can produce custom Brass parts in various shapes and grades, including Brass C260 and C360.

Aluminum is a silver-colored, low-density metal used in a wide range of commercial applications. Under most conditions, unalloyed aluminum is ductile, has moderate strength, and is highly corrosion-resistant. Appropriate alloying elements (Cu, Mg, Mn, Si, etc.) and subsequent heat/work treatments can significantly strengthen aluminum. Because of its low density and corrosion resistance is widely used in aerospace, transportation, architectural, food, and chemical handling (cookware, pressure vessels, etc.) industries.

We provide complete Aluminum CNC machining service and can produce custom Aluminum parts in a variety of shapes and grades, including 1100, 2011, 2024, 3003, 4017, 5052, 6061, 6063, and 7075.

Surface Finishing Options

At Seamark Prototype, we understand that the perfect finish can make all the difference in your product’s performance, durability, and market appeal. Our comprehensive finishing services go beyond mere aesthetics, offering functional enhancements that can significantly improve your parts’ properties. From sleek, polished surfaces to robust, corrosion-resistant coatings, we provide a diverse array of finishing options tailored to your specific needs.

Anodizing: This electrochemical process creates a protective oxide layer on the surface of aluminum parts, providing corrosion resistance and a range of color options.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint, which is applied with an evaporating solvent, powder coating is typically applied electrostatically and cured with heat or ultraviolet light.

Bead blasting produces a smooth, matte-textured surface, and sharp edges can be broken and deburred for safe handling. Bead blasting can also improve the mechanical strength, wear resistance and corrosion resistance of parts.

Electroplating is the process of coating an object in a layer of metal using electrodeposition. Electroplating is widely used to improve the surface qualities of metals, such as resistance to abrasion and corrosion, lubricity, reflectivity, and electrical conductivity. Electroplating can also make metals look better.

Polishing is a technique for creating a smooth and shiny surface by rubbing it or applying a chemical treatment. The process creates a surface with significant specular reflection, but it can also reduce diffuse reflection in some materials.

Brushing is a surface treatment process in which an abrasive belt is used to draw marks and lines on the surface of products to achieve a decorative texture.

Why Us

At Seamark, we pride ourselves on our extensive expertise in the mechanical engineering. Our team of professionals is dedicated to providing the highest quality products and services to our customers.

Expertise

Our team comprises highly skilled engineers, technicians, and craftsmen with years of industry experience. Their deep knowledge spans various manufacturing processes, materials, and industries, allowing us to provide expert guidance throughout your project.

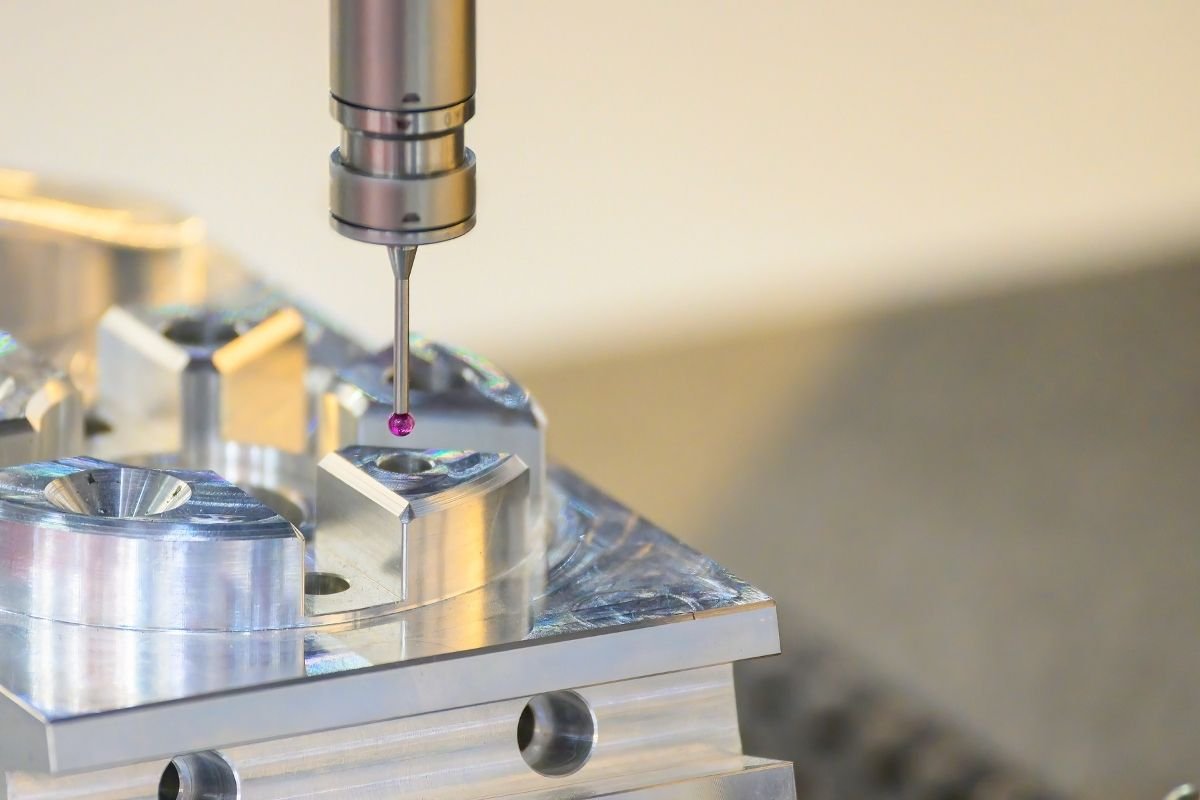

Quality Assurance

We use advanced measurement and testing equipment to verify dimensional accuracy, material properties, and functional performance. Our commitment to quality extends beyond the physical product to encompass our customer service, project management, and delivery processes, ensuring a superior experience from start to finish.

Fast Turnaround

Our ability to quickly iterate on designs and produce functional prototypes can significantly accelerate your product development cycle. With Seamark Prototype, you can bring your products to market faster, gaining a competitive edge in your industry.

Frequently Asked Questions

Absolutely. We provide a range of post-processing services includiWe accept most common 3D CAD file formats, including:

- STL (preferred)

- OBJ

- STEP

- IGES

- Solidworks files (.sldprt, .sldasm) If you have a different file format, please contact us, and we’ll do our best to accommodate your needs.

ng surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.

Turnaround times vary depending on the complexity of the project and the manufacturing method used. For simple projects, we can often deliver within 3-5 business days. More complex projects may take 1-2 weeks. We recommend contacting us directly for a more accurate estimate based on your specific requirements.

While we primarily work with customer-provided 3D models, we do offer basic design assistance and can help refine your existing designs for manufacturability. For more extensive design work, we can recommend trusted partners or discuss your needs on a case-by-case basis.

We work with a wide range of materials including various plastics, metals, and composites. Our capabilities include ABS, PLA, and resin for 3D printing; aluminum, steel, and other metals for CNC milling and sheet metal work; and a variety of resins for vacuum casting. We can discuss specific material requirements for your project.

Yes, we specialize in both rapid prototyping and low-volume manufacturing. Our services are scalable, allowing us to produce anywhere from a single prototype to several hundred units, depending on your needs and the manufacturing method used.

Absolutely. We provide a range of post-processing services including surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.