About Seamark

At Seamark Prototype, we specialize in bringing your ideas to life. Based in Shenzhen, we offer cutting-edge prototyping and low-volume manufacturing solutions for innovators worldwide. From rapid prototyping to bespoke production, we’re your one-stop partner for turning concepts into tangible products.

Full-line Prototyping Service

At Seamark Prototype, we pride ourselves on being your comprehensive manufacturing partner. From initial concept to finished product, we handle every aspect of the process under one roof.

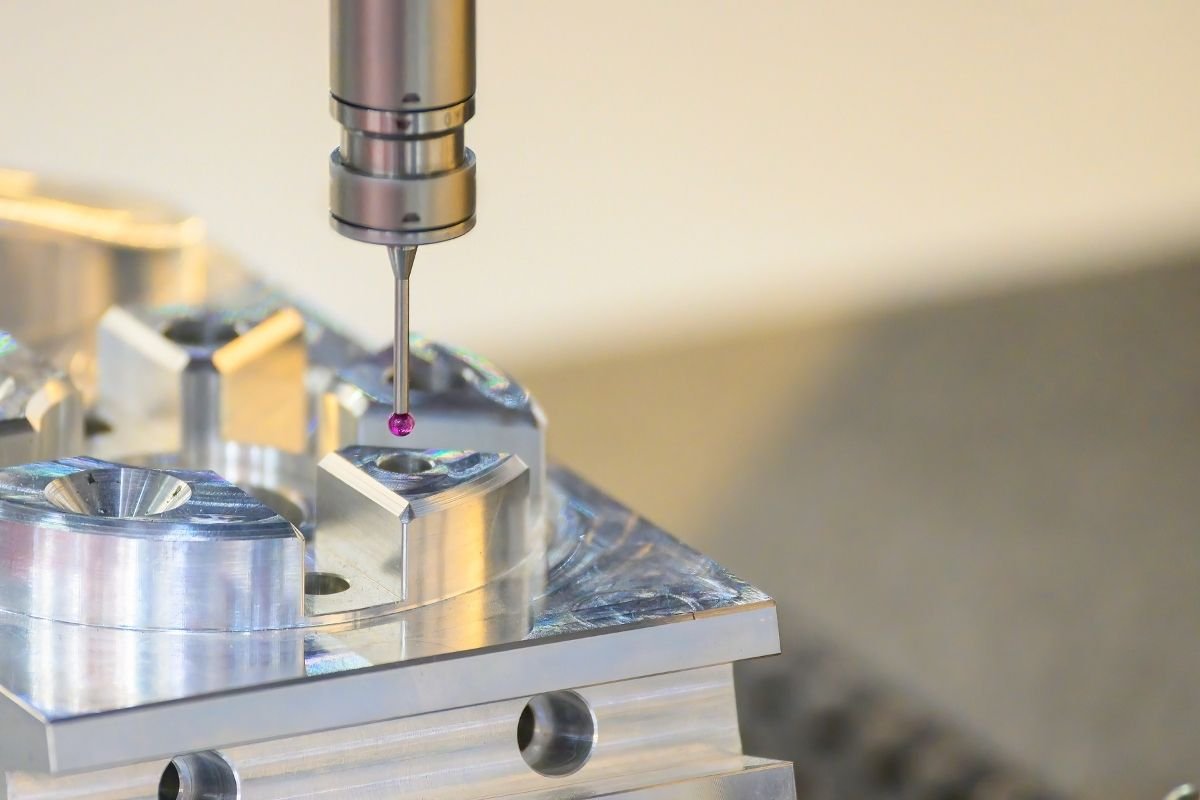

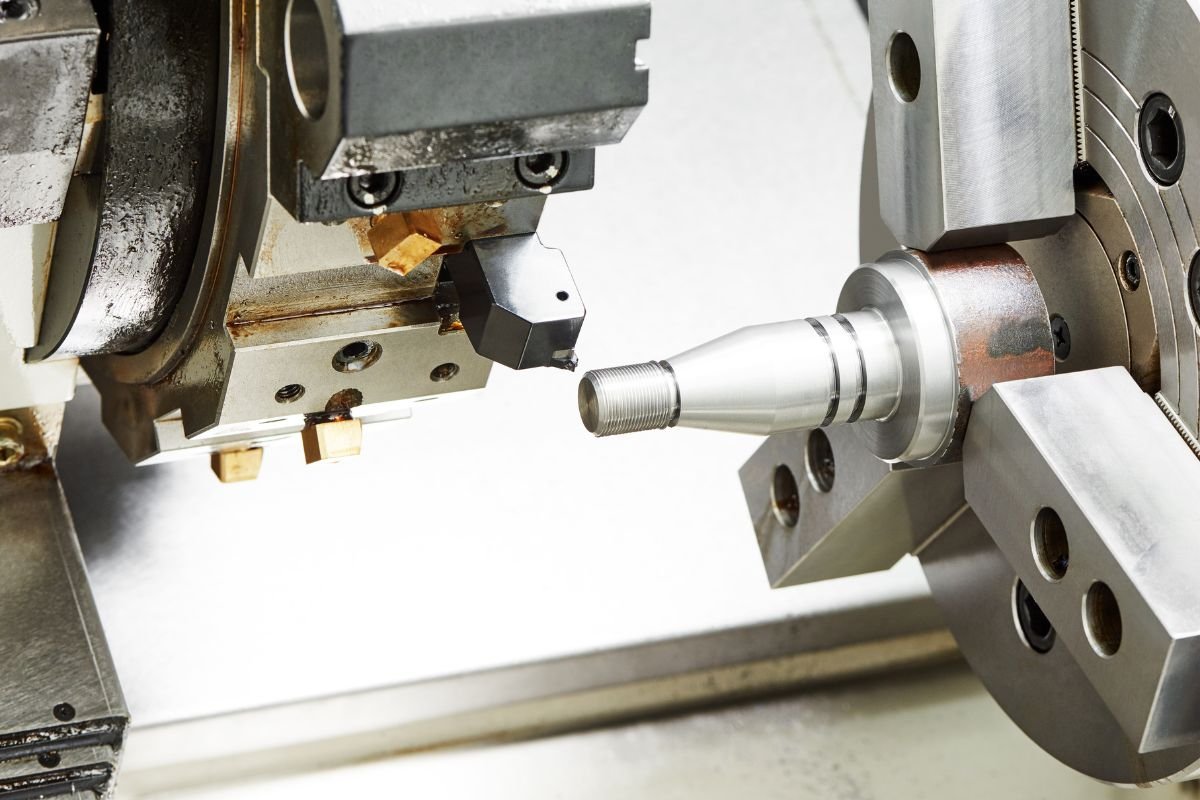

Die präzise und vielseitige CNC-Bearbeitung bietet hochwertige, kundenspezifische Teile mit engen Toleranzen, die für verschiedene Materialien geeignet sind

Die Blechfertigung ist ideal für komplexe Designs und bietet langlebige und kostengünstige Lösungen für Gehäuse, Halterungen und andere Metallkomponenten

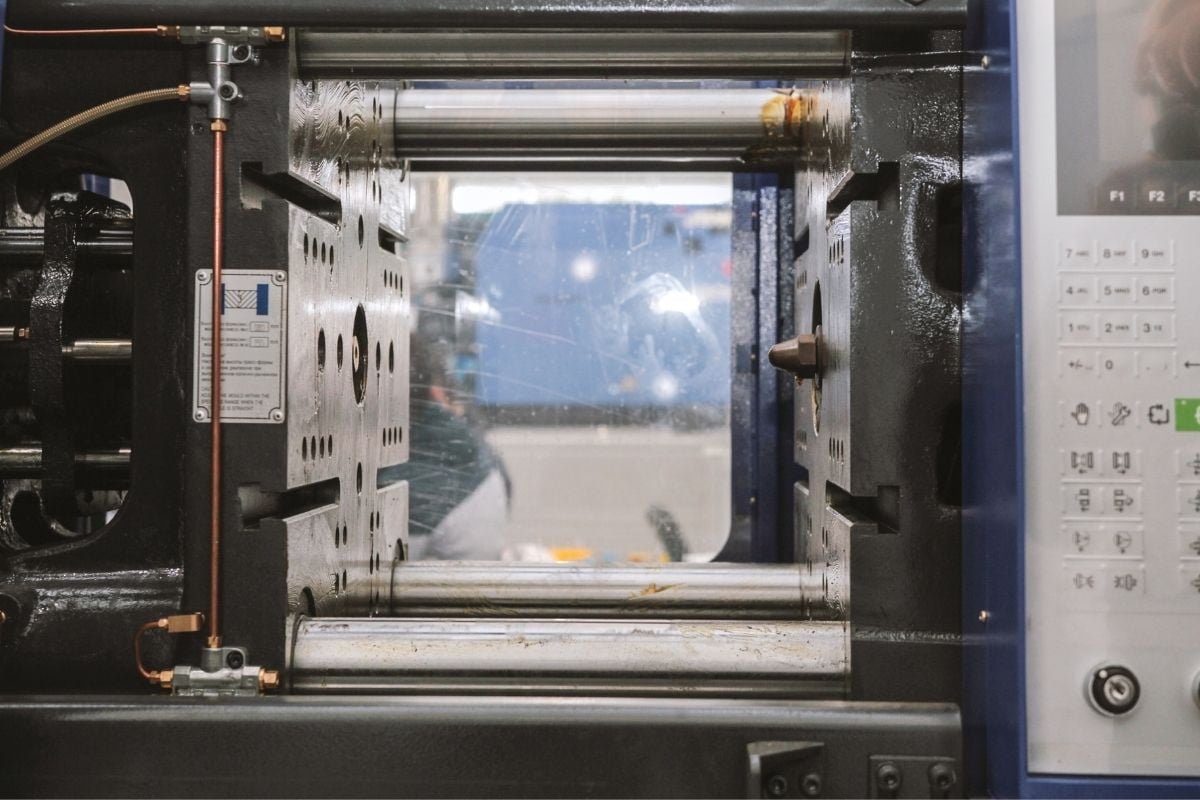

Das effiziente und skalierbare Spritzgießen ermöglicht die Massenproduktion von Kunststoffteilen mit hervorragender Wiederholgenauigkeit und komplizierten Details

Whether to verify market demand before full ramp-up or supply niche industries, Seamark provides a flexible, responsive low-volume production solution.

Warum wir

Our diverse capabilities in CNC milling, 3D printing, vacuum casting, sheet metal fabrication, and more allow us to select the best manufacturing method for each component of your project. This versatility ensures optimal quality, cost-effectiveness, and efficiency throughout your product’s development cycle.

Quality Control

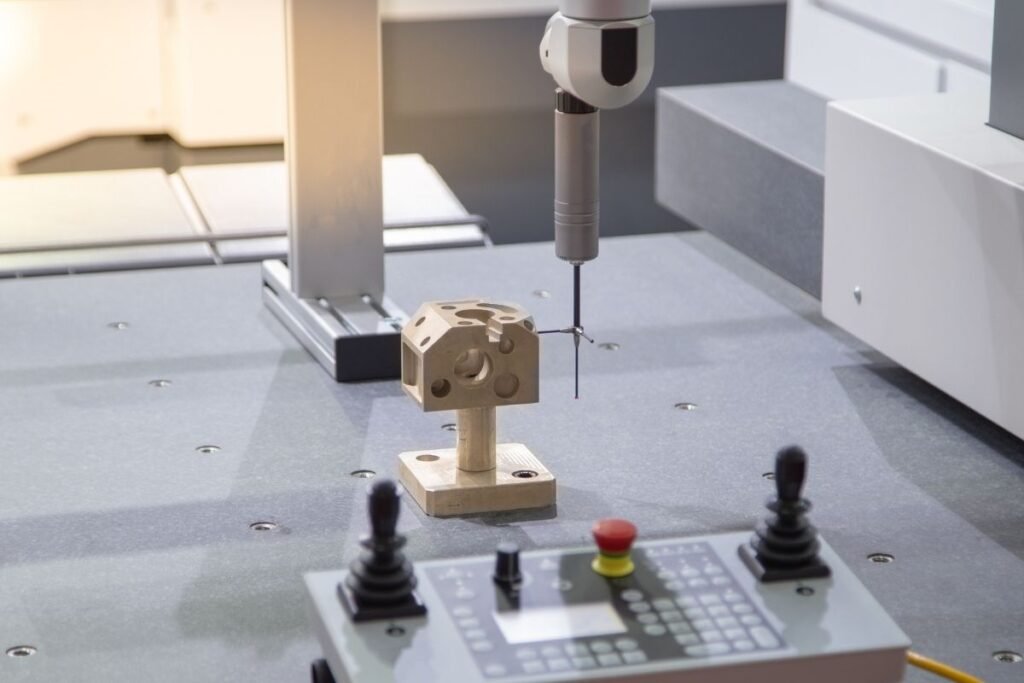

Rigorous quality control measures are implemented at every stage of production

Cost-Effective

Eliminates the need for multiple vendors, significantly reducing overall costs for clients.

Pünktliche Lieferung

In-house capabilities and streamlined workflows for quick turnaround times

Full-line Service

Full-line manufacturing processes under one roof, offering from design assistance to final assembly

Accelerate Your Product Development

Time-to-market matters. With Seamark Prototype’s rapid prototyping and production services, you can fast-track your product development cycle. Request a quote now and discover how we can help you stay ahead of the competition.

Ready to move from prototype to production? Seamark Prototype offers seamless scaling solutions. Whether you need 10 or 10,000 units, we’ve got you covered.

Branchen, die wir bedienen

Seamark work with a wide range of materials, from plastics to metals, allows them to meet the specific needs of different industry.

01.

Luft- und Raumfahrt

Bearbeitung kundenspezifischer Metall- und Kunststoffkomponenten für Flugzeuge

02.

Automobil

Motorteile, Getriebekomponenten sowie Innen- und Außenverkleidungsteile

03.

Elektronik

Präzisionsgehäuse aus Metall und Kunststoff für elektronische Geräte, Prototypen

04.

Medizinische Industrie

Metall- und Kunststoffgehäuse und Prototypen für Diagnosegeräte und Patientenüberwachungssysteme

05.

Robotik

Präzisionsbearbeitung von Metall- und Kunststoffgehäusen, Prototypen

06.

Industrielle Maschinen

Gehäuseteile aus Metall und Kunststoff für verschiedene Geräte wie Pumpen, Motoren, Ventile und Bedienfelder

07.

Konsumgüter

Herstellung von Metall- und Kunststoffgehäusen, Prototypen für Unterhaltungselektronik.

08.

Energie und erneuerbare Energien

Metall- und Kunststoffteile, Gehäuse für Energieerzeugungsanlagen.

Ready to move from prototype to production

Experience One-Stop Manufacturing Excellence

Happy Clients

What Our Clients Say

Unser Ziel ist es, ein vertrauenswürdiger Partner und eine treibende Kraft in der Zerspanungsindustrie zu sein und zum Erfolg und Wachstum unserer Kunden beizutragen.

Häufig gestellte Fragen

Absolutely. We provide a range of post-processing services includiWe accept most common 3D CAD file formats, including:

- STL (preferred)

- OBJ

- STEP

- IGES

- Solidworks files (.sldprt, .sldasm) If you have a different file format, please contact us, and we’ll do our best to accommodate your needs.

ng surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.

Turnaround times vary depending on the complexity of the project and the manufacturing method used. For simple projects, we can often deliver within 3-5 business days. More complex projects may take 1-2 weeks. We recommend contacting us directly for a more accurate estimate based on your specific requirements.

While we primarily work with customer-provided 3D models, we do offer basic design assistance and can help refine your existing designs for manufacturability. For more extensive design work, we can recommend trusted partners or discuss your needs on a case-by-case basis.

We work with a wide range of materials including various plastics, metals, and composites. Our capabilities include ABS, PLA, and resin for 3D printing; aluminum, steel, and other metals for CNC milling and sheet metal work; and a variety of resins for vacuum casting. We can discuss specific material requirements for your project.

Yes, we specialize in both rapid prototyping and low-volume manufacturing. Our services are scalable, allowing us to produce anywhere from a single prototype to several hundred units, depending on your needs and the manufacturing method used.

Absolutely. We provide a range of post-processing services including surface finishing, painting, polishing, and assembly. These services ensure that your prototype or product not only functions correctly but also has the desired aesthetic appearance.